Multi Media Filters - (60" High)

Standard Features

- Made in the USA - ASME Code

- Fully Assembled and Tested

- Skid Mounted for easy installation and levelling

- Inlet/outlet and backwash manifolds

- PLC Controller, solenoids, electrical wire, tubing

- Standard carbon steel products, 3/16" thick material

- Backwash automatically initiated by elapsed time or pressure differential

- Easy-entry lid closure with weld tabs for operator safety

- Available in welded carbon steel

- ASME code shaped head construction for durability and safety

- Stainless steel wedgewire removable underdrain

- Structural integrity can withstand the harshest conditions

- Hydraulically balanced to increase effectiveness of backwash while reducing flush frequency and waste of water

- High strength stainless steel wedgewire will withstand a collapse pressure in excess of 600 psi

Applications

- Removal of organic and/or inorganic suspended solids down to 20 microns

- Pre-filtration in applications such as granular activated carbon, reverse osmosis, cartridge or bag filtration and deionized water

- Mining Industry

- Pre-Filtration for RO (Reverse Osmosis)

- Storm water runoff, industrial process water, incoming plant water, waste water clean-up, industrial water for plant reuse

- Oil & Fracking Water

- Construction Remediation

- Stormwater Remediation

- Municipal Process Water

- Nurseries & Greenhouses

System Detailed Overview

Through the use of automatically controlled backwashing, the filter will operate "on-line" for extended periods of time prior to the short backwashing cycle. Automatic filter operation is monitored on both elapsed time as well as pressure differential. When the controller "calls" for a backwash as a result of pressure differential or elapsed time, the backwashing function utilizes a portion of the clean filtered water produced by the system to clean the media bed. Single tank systems utilize unfiltered water for backwashing. Optional external backwash water sourcing systems are available for both single and multiple tank systems.

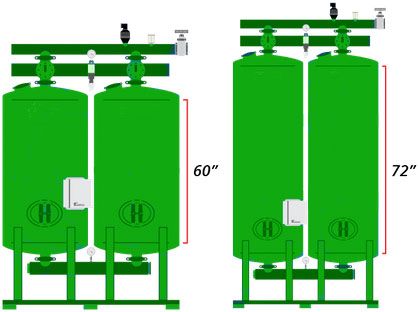

The Ecologix Multi-Media Filter utilizes a vertical side shell depth of 60" with layered graded beds of filtration media. Through the use of multiple layers of specially selected filter media, "progressive filtration" is achieved through the media layers. The first layer of filter media entraps and holds larger sized particles allowing smaller particles to be removed in subsequent media layers. The final media layer "polishes" the water removing suspended solids down to 5 microns in size and smaller.

Our Multi-Media Filters are ideally suited for use where stringent water quality standards are required or where higher levels of suspended solids are present. These applications can include re-use applications, water pre-treatment applications for reverse osmosis and de-ionization systems, or as a pre-treatment system prior to disposable bag or cartridge filters. Our Multi-Media Filters are also widely used as primary filters for removal of suspended solids in incoming plant water or in waste water clean up applications. Air scour and surface wash options are available if required.

Industrial Multi Media Filter Specifications

| Model | # Of Tanks | Min Flow Rates | Max Flow Rates | Filtration Surface Area Ft2 | Backwash Flow Rate (per tank) | Media (Ft3) | Max Pressure | Inlet/Outlet Pipe Size | Backwash Pipe Size | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| US GPM | m3/hr | US GPM | m3/hr | US GPM | m3/hr | Gravel 1/2" - 3/4" | Garnet 1.45mm | Garnet 0.35mm | Anthracite 0.75mm | ||||||

| MM-1860-1A | 1 | 9 | 2 | 26 | 6 | 1.77 | 27 | 6 | 1 | 1 | 2.5 | 2.5 | 100 | 2" | 2" |

| MM-2460-1A | 1 | 16 | 4 | 47 | 11 | 3.15 | 47 | 11 | 2 | 2 | 5 | 5 | 100 | 2" | 2" |

| MM-1860-2A | 2 | 18 | 4 | 53 | 12 | 3.54 | 27 | 6 | 1 | 1 | 2.5 | 2.5 | 100 | 2" | 2" |

| MM-3060-1A | 1 | 25 | 6 | 74 | 17 | 4.91 | 74 | 17 | 3 | 3 | 8 | 8 | 100 | 3" | 3" |

| MM-1860-3A | 3 | 27 | 6 | 79 | 18 | 5.31 | 27 | 6 | 1 | 1 | 2.5 | 2.5 | 100 | 3" | 2" |

| MM-2460-2A | 2 | 32 | 7 | 95 | 22 | 6.30 | 47 | 11 | 2 | 2 | 5 | 5 | 100 | 3" | 2" |

| MM-3660-1A | 1 | 35 | 8 | 107 | 24 | 7.10 | 107 | 24 | 4 | 4 | 11 | 11 | 100 | 3" | 3" |

| MM-2460-3A | 3 | 48 | 11 | 142 | 32 | 9.45 | 47 | 11 | 2 | 2 | 5 | 5 | 100 | 3" | 2" |

| MM-3060-2A | 2 | 50 | 11 | 147 | 33 | 9.82 | 74 | 17 | 3 | 3 | 8 | 8 | 100 | 4" | 2" |

| MM-4860-1A | 1 | 63 | 14 | 189 | 43 | 12.60 | 189 | 43 | 7 | 7 | 19 | 19 | 80 | 4" | 4" |

| MM-3060-3A | 3 | 75 | 17 | 221 | 50 | 14.73 | 74 | 17 | 3 | 3 | 8 | 8 | 100 | 4" | 2" |

| MM-5460-1A | 1 | 80 | 18 | 239 | 54 | 15.91 | 239 | 54 | 10 | 8 | 24 | 24 | 80 | 4" | 4" |

| MM-3660-3A | 3 | 105 | 24 | 320 | 73 | 21.30 | 107 | 24 | 4 | 4 | 11 | 11 | 100 | 4" | 3" |

| MM-4860-2A | 2 | 126 | 29 | 378 | 86 | 25.20 | 189 | 43 | 7 | 7 | 19 | 19 | 80 psi | 6" | 4" |

| MM-5460-2A | 2 | 160 | 36 | 477 | 108 | 31.82 | 239 | 54 | 10 | 8 | 24 | 24 | 80 psi | 6" | 4" |

| MM-4860-3A | 3 | 189 | 43 | 567 | 129 | 37.80 | 189 | 43 | 7 | 7 | 19 | 19 | 80 psi | 6" | 4" |

| MM-5460-3A | 3 | 240 | 55 | 716 | 163 | 47.73 | 239 | 54 | 10 | 8 | 24 | 24 | 80 psi | 6" | 4" |

| MM-4860-4A | 4 | 252 | 57 | 756 | 172 | 50.40 | 189 | 43 | 7 | 7 | 19 | 19 | 80 psi | 8" | 4" |

| MM-5460-4A | 4 | 300 | 60 | 900 | 216 | 62.50 | 239 | 54 | 10 | 8 | 24 | 24 | 80 psi | 8" | 4" |

| MM-4860-6A | 6 | 378 | 86 | 1134 | 258 | 75.60 | 189 | 43 | 7 | 7 | 19 | 19 | 80 psi | 10" | 4" |

| MM-5460-5A | 5 | 400 | 91 | 1193 | 271 | 79.55 | 239 | 54 | 10 | 8 | 24 | 24 | 80 psi | 10" | 4" |

| MM-5460-6A | 6 | 480 | 109 | 1432 | 325 | 95.46 | 239 | 54 | 10 | 8 | 24 | 24 | 80 psi | 10" | 4" |

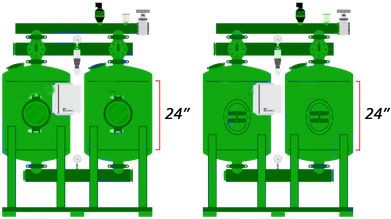

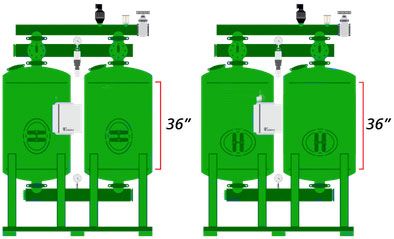

Multimedia Filter Scaling

A comparison of the available filter heights.

Available Options

- ASME Code Vessels

- Stainless Steel 304SS or 316SS

- High Pressure 90+ PSI

- PLC Integration

- Electric Valve Operation

- NEMA 4X Enclosure

- Custom Piping Design

Advantages

- Our filtration systems provide exceptional results, rigorously tested and tuned for industrial applications

- Self cleaning backwash features use water internal to the system

- Industrial grade stainless steel solenoids versus industry standard plastic solenoids

- 80 PSI max standard operating capable

- SS304 backwash control enclosure versus industry standard carbon steel or plastic

- Fabricated backwash manifolds