Summary

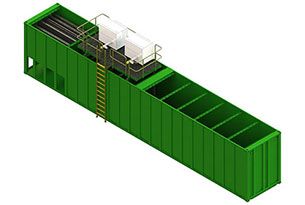

As discharge permits for Nitrogen and Phosphorus become more stringent, many industrial and municipal facilities find that their traditional lagoon systems can no longer keep up. Instead of the massive capital expense of building new concrete basins, many operators are turning to Lagoon Intensification using MBBR (Moving Bed Biofilm Reactor) and IFAS (Integrated Fixed-film Activated Sludge) designs.

At Ecologix Environmental Systems, we specialize in retrofitting existing infrastructure to expand capacity and improve effluent quality without expanding the plant's footprint.

Contact us today to learn more

We offer a free assessment of your wastewater treatment needs.

Contact UsWhat is the Difference Between MBBR and IFAS?

While both technologies utilize specialized media (carriers) to grow biomass, they serve different operational goals:

- MBBR (Moving Bed Biofilm Reactor): A "once-through" process where 100% of the biomass grows on the submerged, moving media. There is no sludge recycled (RAS) or returned to the MBBR zone. It is ideal for high-load industrial pre-treatment without the need for nitrogen removal.

- IFAS (Integrated Fixed-film Activated Sludge): A hybrid system that combines fixed-film media with traditional suspended growth (activated sludge). By returning sludge (RAS) to a tank containing MBBR media, you get additional treatment power with built-in robustness in the same space.

Why Upgrade Your Lagoon?

Traditional lagoons are limited by temperature and surface area. In winter, biological activity slows down, often leading to permit violations for ammonia (NH3 -N).

The MBBR/IFAS Advantage:

- Increased Capacity: Add up to 300% more biomass to your existing lagoon volume.

- Nitrification in Cold Weather: The protected surface area of the media allows nitrifying bacteria to thrive even when water temperatures drop.

- Process Stability: Biofilms are highly resilient to "shock loads" or toxic spikes compared to traditional activated sludge.

- No New Footprint: Avoid the permitting and construction nightmares of building new ponds.

Step-by-Step: The Lagoon Retrofit Process

- Retention & Screening

To convert a lagoon to MBBR or IFAS, Ecologix installs stainless steel retention screens at the outlet. This ensures the biofilm carriers stay in the lagoon while treated water passes through.

- Media Selection (The Heart of the System)

Ecologix utilizes its own high-surface-area media (called Eco Chips) designed for maximum oxygen transfer. Our media is engineered to prevent "clogging" while providing a protected home for the bacteria.

- Aeration & Mixing

We replace or augment traditional surface aerators with fine bubble aeration or coarse bubble grids. This serves two purposes: providing the necessary dissolved oxygen (DO) for the bacteria and keeping the media in constant motion to ensure contact with the wastewater.

- Optional: The IFAS Hybrid Setup

If your lagoon requires extremely low effluent limits for Total Nitrogen, we configure the system as an IFAS unit. By maintaining a MLSS (Mixed Liquor Suspended Solids) population alongside the media, we achieve superior solids settling and nutrient removal.

Comparison: MBBR vs. IFAS for Lagoon Upgrades

| Feature | MBBR Retrofit | IFAS Retrofit |

|---|---|---|

| Best For | BOD Removal / Pre-treatment | Nutrient Removal / Low Ammonia limits |

| Sludge Recycle (RAS) | Not Required | Required |

| Operational Ease | Highest (Set and forget) | Moderate (Requires sludge management) |

| Cold Weather Performance | Excellent | Superior |

| Footprint Impact | Zero (Internal) | Zero (Internal) |

The Ecologix Edge: Why Partner With Us?

Upgrading a lagoon is more than just throwing plastic media into a pond. It requires precise oxygen-transfer calculations and hydraulic modeling.

- Custom Media Sizing: We don't believe in one-size-fits-all. We calculate the specific surface area needed based on your influent BOD/TSS.

- Integrated Solutions: Ecologix can pair your biological upgrade with our E-DAF (Enhanced Dissolved Air Flotation) system for superior solids removal downstream.

- USA-Based Engineering: Our systems are designed and supported by our team in Alpharetta, Georgia, ensuring rapid response and technical expertise.

Optimize Your Facility Today

Is your lagoon reaching its limit? Don't build a new pond—intensify the one you have.

Contact Ecologix Environmental Systems for a process evaluation and see how an MBBR or IFAS upgrade can bring your facility back into compliance.