The metal plating and finishing industry faces significant wastewater challenges. While heavy metal removal is a primary focus, meeting stringent limits for nitrogen compounds—specifically ammonia (NH₃) and nitrates (NO₃)—is a growing operational hurdle. Ecologix Systems provides a targeted, high-efficiency biological solution with our Moving Bed Biofilm Reactor (MBBR).

The Challenge: Nitrogen in Plating Effluent

Wastewater from plating, cleaning, and rinsing processes is often rich in ammonia and other nitrogen compounds. This stream is also frequently laden with residual chemicals, heavy metals, and experiences sharp fluctuations in pH and temperature.

These conditions are highly toxic to the sensitive microbes used in conventional wastewater systems, leading to process upsets, inconsistent treatment, and non-compliance with discharge permits.

The Solution: A Robust MBBR System

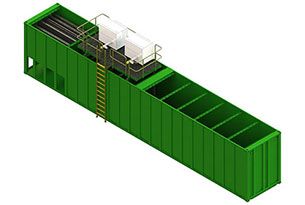

The Ecologix MBBR is engineered to thrive in the harsh conditions of metal finishing wastewater. The core of the system is a protected, self-regulating biofilm that grows on thousands of specially designed media carriers within the reactor. This robust biological colony is highly resistant to toxic shock and process variations.

Our MBBR systems are configured to achieve complete nitrogen removal through a two-step process:

- Nitrification: In an aerobic (oxygen-rich) reactor, one set of bacteria converts toxic ammonia into nitrates.

- Denitrification: The water then flows to an anoxic (low-oxygen) reactor, where a different set of bacteria converts nitrates into harmless nitrogen gas (N₂), which is safely released into the atmosphere.

Key Advantages for Metal Finishers

Consistent Compliance

The resilient biofilm provides stable, reliable nitrification and denitrification, ensuring you consistently meet even the strictest ammonia and nitrate discharge limits.

Compact Footprint

MBBR systems are significantly smaller than conventional activated sludge systems, saving valuable plant space for production.

Resilience to Toxicity

The protected biofilm can withstand the chemical shocks and variable loads common in metal finishing, preventing the system crashes that plague other biological processes.

Low Maintenance & Automation

The self-regulating nature of the biofilm requires minimal operator intervention, reducing labor costs and complexity.