For producers of soft drinks, juices, beer, and other beverages, wastewater treatment is a major challenge. Effluent is characterized by extremely high Biological Oxygen Demand (BOD) from sugars, syrups, and flavorings, alongside dramatic pH swings from cleaning cycles. Ecologix Systems' MBBR is engineered to handle these demanding conditions reliably and efficiently.

The Challenge: Sugars, Acids, and Alkalis

Beverage wastewater is notoriously difficult to treat with conventional systems for three key reasons:

- Extreme Organic Loading: Spilled product, tank washouts, and fruit pulp result in massive BOD spikes that can overwhelm standard treatment plants.

- Wild pH Swings: Aggressive acidic and alkaline cleaners used in Clean-In-Place (CIP) systems can kill the sensitive microorganisms needed for biological treatment.

- Nutrient Deficiency: Sugary waste often lacks the necessary nitrogen and phosphorus for healthy biological activity, requiring costly chemical additions.

The Solution: A High-Rate MBBR System

The Ecologix Moving Bed Biofilm Reactor is the perfect technology for the beverage industry. It creates an ideal environment for a specialized, robust biomass to thrive.

The core of the system is the vast, protected surface area on our Eco Chip biocarriers. This allows a dense, powerful biofilm to grow, which can rapidly metabolize the high concentrations of sugar and organic matter. This biofilm is incredibly resilient, quickly recovering from the pH swings of CIP dumps that would devastate other systems.

Key Advantages for Beverage Producers

Reliable BOD & COD Reduction

Consistently meet and exceed municipal discharge limits, avoiding costly surcharges and fines associated with high-strength waste.

Operational Stability

The resilient, self-regulating biofilm handles fluctuating loads from different production runs and cleaning cycles without operator intervention.

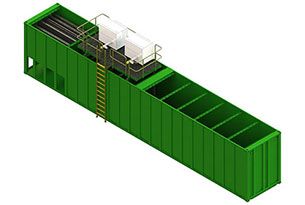

Compact Design

An MBBR system requires a fraction of the space of a conventional activated sludge plant, freeing up valuable real estate for production expansion.

Reduced Chemical Costs

The highly efficient biological process minimizes the need for expensive pH adjustment chemicals and nutrient additives.