The food and beverage industry faces unique challenges in wastewater treatment, primarily due to high concentrations of organic matter (BOD/COD), fats, oils, and grease (FOG). These components, stemming from processes like dairy production, meat processing, brewing, and bottling, demand adaptable treatment solutions to meet stringent discharge regulations.

Moving Bed Biofilm Reactor (MBBR) technology offers an ideal solution. Its compact design and high treatment efficiency make it perfectly suited for facilities with limited space and fluctuating wastewater characteristics.

5 Reasons Why MBBR Excels in Food & Beverage Wastewater

1. High Organic Load Handling

Food and beverage wastewater is characterized by high Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD). MBBR systems, with their continuously moving biofilm carriers, provide a large, active surface area for microbial growth. This allows for a high concentration of biomass, capable of efficiently degrading significant organic loads, ensuring your effluent meets regulatory limits.

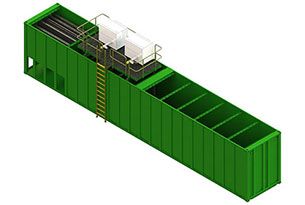

2. Compact Footprint

Many food and beverage facilities operate within constrained footprints. MBBR's ability to achieve high treatment rates in smaller tank volumes means you can implement or upgrade your wastewater treatment system without requiring extensive land or costly civil works. This is a significant advantage over traditional activated sludge systems.

3. Resilience to Fluctuations

Production schedules in the food and beverage industry can lead to significant variations in wastewater flow and pollutant concentration (shock loads). The robust biofilm in an MBBR system is highly resilient to these fluctuations, maintaining stable treatment performance and preventing costly non-compliance issues.

4. Reduced Sludge Production

Compared to conventional activated sludge, MBBR systems typically produce less excess sludge. This translates directly into lower sludge handling and disposal costs, offering significant operational savings for your facility.

5. Low Maintenance & Operational Simplicity

MBBR systems are known for their operational simplicity. They do not require sludge recirculation or backwashing of media, reducing the need for constant operator intervention and complex controls. This leads to lower maintenance requirements and more reliable long-term performance.

Ready to Improve Your Food & Beverage Wastewater Treatment?

Contact us today for a free wastewater assessment and learn how an Ecologix MBBR can benefit your specific Food & Beverage operation.

678-514-2100 Request a Quote