Introduction

In the world of industrial water treatment, efficiency, reliability, and cost-effectiveness are paramount. Industries such as food processing, petrochemicals, and pulp and paper generate high-strength wastewater that demands robust treatment solutions to meet strict regulatory standards and achieve sustainability goals. Enter Moving Bed Biofilm Reactor (MBBR) technology—a revolutionary approach that has transformed how industries manage wastewater. At Ecologix Environmental Systems, we've seen firsthand how MBBR systems deliver unparalleled performance, making them a game-changer for industrial water treatment. Here's why.

What is MBBR Technology?

MBBR technology is a biological wastewater treatment process that combines the benefits of traditional activated sludge systems and fixed-film processes. In an MBBR system, free-floating plastic media, or biofilm carriers, provide a surface for microorganisms to grow and form a biofilm. These microorganisms degrade organic matter and pollutants in the wastewater, effectively treating it. The media are kept in constant motion by aeration or mechanical mixing, ensuring optimal contact between the biofilm and the wastewater.

Unlike conventional systems, MBBR is compact, flexible, and highly efficient, making it ideal for industries with complex wastewater streams or limited space. Its ability to handle high organic loads and adapt to varying conditions has made it a go-to solution for modern wastewater treatment.

Key Advantages of MBBR Technology

- Compact Design for Space-Constrained Facilities

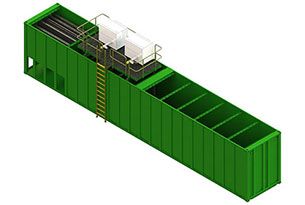

Industrial facilities often face space limitations, especially when retrofitting existing wastewater treatment systems. MBBR systems require significantly less footprint than traditional activated sludge processes or fixed-bed reactors. The high biomass concentration on the biofilm carriers allows for efficient treatment in smaller tanks, reducing capital costs for land and infrastructure.

For example, a food processing plant with limited space can implement an MBBR system to treat high-BOD (Biochemical Oxygen Demand) wastewater without needing extensive construction. At Ecologix, our custom-engineered MBBR solutions are designed to maximize treatment capacity within your facility's spatial constraints. - High Treatment Efficiency for Tough Wastewater

Industrial wastewater often contains high levels of organic matter, nitrogen, or other pollutants that challenge conventional treatment systems. MBBR technology excels at treating these complex streams. The biofilm carriers support a diverse microbial community capable of degrading a wide range of contaminants, including COD (Chemical Oxygen Demand), BOD, and ammonia.

In industries like pulp and paper or petrochemicals, where wastewater composition can vary, MBBR systems maintain consistent performance. The biofilm's resilience ensures stable treatment even during shock loads or fluctuations in influent quality, helping facilities meet stringent discharge regulations. - Low Operating Costs and Energy Efficiency

Energy consumption is a major concern for industrial wastewater treatment. MBBR systems are designed for energy efficiency, requiring less aeration than traditional activated sludge processes. The biofilm carriers enhance oxygen transfer, reducing the need for excessive air pumping. Additionally, MBBR systems produce less sludge than conventional methods, lowering sludge handling and disposal costs.

For instance, an Ecologix MBBR system can reduce sludge production by up to 30% compared to activated sludge systems, translating to significant savings for clients in industries like oil and gas. These cost efficiencies make MBBR an attractive option for facilities aiming to optimize their operational budgets. - Flexibility and Scalability

One of MBBR's standout features is its modular design, which allows for easy scalability and adaptability. Whether you're expanding production or upgrading your treatment system to meet new regulations, MBBR systems can be scaled up by adding more biofilm carriers or tanks. This flexibility minimizes downtime and avoids the need for costly overhauls.

Ecologix has successfully implemented modular MBBR systems for clients who needed to increase treatment capacity during peak production seasons. This adaptability ensures your wastewater treatment system evolves with your business. - Low Maintenance and Robust Performance

MBBR systems are low-maintenance and highly reliable. The biofilm carriers are durable, self-regulating, and resistant to clogging, reducing the need for frequent cleaning or replacement. The system's simplicity—no need for sludge recycling or complex controls—means fewer operational headaches for facility managers.

In a real-world example, a chemical manufacturing client using an Ecologix MBBR system reported minimal maintenance over five years of operation, with consistent compliance to EPA discharge standards. This reliability is critical for industries where downtime can lead to production losses.

Applications of MBBR in Industry

MBBR technology is versatile and suited for a wide range of industrial applications:

- Food and Beverage Industry: Treats high-BOD wastewater from dairy, meat processing, or beverage production, ensuring compliance with BOD and TSS regulations.

- Oil and Gas Industry: Manages produced water or refinery effluents, removing soluble organics and other contaminants.

- Pulp and Paper Industry: Handles high-organic-load wastewater while supporting water reuse initiatives.

- Chemical Manufacturing Industry: Treats complex chemical effluents with varying pollutant levels.

- Municipal-Industrial Hybrid Facilities: Enhances treatment capacity for facilities serving both industrial and municipal wastewater.

Why Choose Ecologix for MBBR Solutions?

At Ecologix Environmental Systems, we specialize in designing and implementing custom MBBR systems tailored to your facility's unique needs. Our team conducts thorough wastewater characterization and treatability studies to ensure optimal system performance. We also integrate advanced monitoring and automation, allowing you to track treatment efficiency in real time and minimize operational costs.

Our MBBR systems are built with high-quality, corrosion-resistant materials, ensuring long-term durability in harsh industrial environments. Plus, our comprehensive support—from system design to maintenance—ensures your wastewater treatment operations run smoothly.

The Future of Wastewater Treatment

As industries face increasing pressure to reduce environmental impact and operational costs, MBBR technology stands out as a forward-thinking solution. Its compact design, high efficiency, and flexibility make it an essential tool for achieving compliance, sustainability, and cost savings. With global water scarcity concerns and stricter regulations on the horizon, MBBR is poised to play a central role in the future of industrial water treatment.

Take the Next Step with Ecologix

If your facility is struggling with high treatment costs, limited space, or complex wastewater streams, MBBR technology could be the solution you've been searching for. Contact Ecologix Environmental Systems today for a free wastewater treatment assessment. Our experts will work with you to design a custom MBBR system that meets your needs and drives your business forward.

678-514-2100 Contact Ecologix