Introduction: Rethinking Wastewater Management

For over a century, cities have relied on centralized plants to treat wastewater collected via extensive pipes. This model supports public health but demands high energy, costly infrastructure, and risks widespread failures.

Localized treatment systems process wastewater near its source, offering flexibility to address modern challenges like water scarcity and environmental adaptability. For environmental engineering, understanding decentralized wastewater systems (DWS) is key to mastering sustainable water management. DWS apply core principles like mass balance (tracking pollutants through treatment), pollutant fate and transport (how contaminants move or transform), and sustainability (balancing environmental, economic, and community needs).

What Is a Decentralized Wastewater System?

Localized systems treat wastewater close to its generation point using compact units, reducing the need for extensive pipe networks. This cuts energy use, lowers costs, and allows tailored designs for specific sites.

Wastewater Composition: The following table shows approximate values for typical untreated domestic wastewater (e.g., from households; actual values vary based on location, diet, and water use). Industrial wastewater, like produced water from oil and gas operations, differs significantly, containing high total dissolved solids (1,000-400,000 mg/L), oil and grease (2-500 mg/L), heavy metals, and hydrocarbons, requiring specialized treatment.

| Parameter | Description | Typical Range (mg/L) for Domestic Wastewater |

|---|---|---|

| BOD | Organic matter consuming oxygen | 100-400 |

| TSS | Suspended solids | 100-350 |

| Nitrogen | Nutrient causing eutrophication | 20-85 |

| Phosphorus | Nutrient causing algal blooms | 4-15 |

Why Choose Decentralized? Key Drivers and Benefits

Onsite systems address gaps in centralized infrastructure, such as remote locations or overloaded grids. Benefits include:

- Environmental Gains: Lower energy for pumping (0.1-0.3 kWh/m3 vs. 0.5-1 kWh/m3 for centralized systems); easier reuse for irrigation; nutrient/energy recovery potential.

- Economic Savings: Avoids costly pipe extensions (e.g., $10,000-$50,000/km); supports phased investments; reduces operational costs.

- Resilience: Distributed setup limits widespread disruptions.

- Adaptability: Enables tailored governance and scalable growth.

| Feature | Centralized | Decentralized |

|---|---|---|

| Collection Network | Extensive pipes over long distances | Minimal pipes over short distances |

| Treatment Location | Single large facility | Multiple small units near sources |

| Energy Consumption | High (0.5-1 kWh/m3) | Lower (0.1-0.3 kWh/m3) |

| Resource Recovery | Challenging due to scale | Easier for local reuse |

| Capital Costs | High ($1,000-$5,000/m3 capacity) | Lower ($500-$2,000/m3 capacity) |

| Operational Costs | High from maintenance | Potentially lower |

| Resilience | Vulnerable to single failures | Distributed risk |

| Adaptability | Less flexible | Highly scalable |

Who and Where: Users and Ideal Locations

Onsite systems suit various users and settings:

| User Type | Rural Areas | Challenging Terrain | Sensitive Ecosystems | Remote Sites | Phased Growth | Water-Scarce Areas | Urban Infill |

|---|---|---|---|---|---|---|---|

| Homeowners | Cost-effective sanitation | Avoids pumping costs | Protects local waters | Viable for off-grid | Adds without strain | Enables irrigation | Sanitation without access |

| Communities | Enables expansion | Simplifies collection | Advanced protection | Basic services | Modular scaling | Supports reuse | Integrates housing |

| Commercial/Industrial | For isolated sites | Reduces piping | Tailored pollutant control | Essential for ops | Accommodates parks | Water recycling | Revitalizes sites |

| Tourist Facilities | Amenities in remote spots | Ideal for resorts | Minimizes impact | Viable sanitation | Incremental expansion | Conservation | Redevelops areas |

| Institutions | Autonomy for campuses | Flexible elevations | Sensitive discharge | Self-contained | Adds buildings | Campus reuse | Modernizes infrastructure |

| Temporary Setups | Rapid deployment | Quick on uneven ground | Mitigates risks | Immediate services | Interim solutions | Essential treatment | Flexible events |

When to Opt for Decentralized: A Decision Framework

Evaluate via these questions:

- Unserved Areas: Is extending sewers too costly? Onsite is often cheaper.

- Infrastructure Strain: Overloaded systems? Localized units offload demand.

- Reuse Goals: Need high-quality effluent? Tailored treatment enables it.

- Phased Projects: Uncertain growth? Modular units align with needs.

- Remote/Temporary: No infrastructure? Portable systems provide quick relief.

- Site Constraints: Tough terrain? Compact designs adapt.

- Sustainability Aims: Focus on resource efficiency and resilience? Distributed approaches excel.

Core Components and Technologies

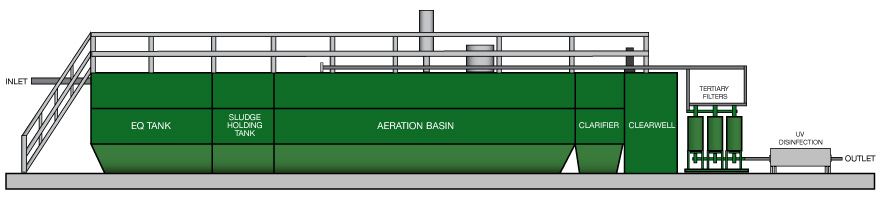

Onsite systems use scaled processes to remove contaminants, tailored to influent and reuse needs. A typical treatment train involves:

Primary Treatment

Removes solids/floatables:

- Septic Tanks: Settling and anaerobic digestion; sized for flow (e.g.,

1,000-1,500 gallons for a 3-bedroom home).

- Example Calculation: For a 3-bedroom home (4 people, 60 gallons/person/day), daily flow = 4 x 60 = 240 gallons/day. Septic tank size = 240 x 3-4 (retention time varies by local standards, typically 1-3 days; 3-4 days used here) = 720-960 gallons, rounded to 1,000 gallons. [2]

- Imhoff Tanks: Separates settling/digestion.

- Clarifiers/DAFs: Large commercial and industrial applications.

- Screens/Grit Chambers: For larger setups.

- Grease Interceptors: For commercial FOG removal.

Secondary Treatment

Biological removal of organics (85-95% BOD/TSS reduction): “Secondary treatment processes, such as sequencing batch reactors and constructed wetlands, typically achieve BOD and TSS removals of 85 to 95 percent, making them effective for decentralized applications where compact, efficient systems are needed.” [10]

- Fixed-Film: Trickling filters or rotating contactors.

- Suspended Growth: Package plants, sequencing batch reactors (SBRs), or Moving Bed Biofilm Reactor (MBBRs).

- Wetlands: Natural filtration via plants/media.

- Example Calculation: For a wetland treating 1,000 gallons/day (3.78 m³/day) with a hydraulic loading rate of 0.02 m³/m²/day, required area = 3.78 ÷ 0.02 = 189 m².

Advanced Treatment

For polished effluent:

- Filtration: Sand, granular activated carbon (GAC), activated glass filtration media (AGFM), or membranes (micro/ultra/nano/reverse osmosis).

- Disinfection: Chlorine, UV, or ozone.

- Nutrient Removal: Biological (nitrification/denitrification) or chemical.

Sludge Management

Handle biosolids via:

- Collection: Periodic pumping (e.g., every 3-5 years for septic tanks or 2-3 weeks for industrial systems).

- Digestion: Anaerobic (biogas production) or aerobic.

- Dewatering: Beds or screw presses.

- Disposal/Reuse: Land application, landfilling, or composting, per EPA Part 503 rules. [3]

Monitoring System Performance

Engineers monitor DWS to ensure compliance with standards (e.g., BOD < 30 mg/L for discharge). Common tests include:

- BOD and TSS: Measure organic matter and solids in effluent via lab analysis.

- pH: Ensures system stability (6.5-8.5 typical range).

- Nutrients: Nitrogen/phosphorus levels to prevent environmental harm.

Real-World Applications

- Oil/Gas in Texas: The Permian Basin in West Texas is home to countless fracking operations for the O&G industry. They are remote with no connection to a centralized grid and even if they could connect the produced water is too filthy and salty for a POTW. Ecologix's Mobile Water Management system ITS-1500 provides a unique integration of a chemical reaction tank and DAF on wheels to allow these sites to treat over 2,000,000 gallons per day per system. [6]

- Packaged Sewage: Ecologix's fabricate scalable packaged plants called Bio-Clear units that treat 3,000 to 100,000 gallons/day each for locations "off the grid" that need to include BOD treatment. These systems integrate screening, equalization, aeration, clarification, and disinfection. These are customized for safe environmental effluent release and reuse. [7]

- Urban Recycling in San Francisco: The SFPUC headquarters treats ~5,000 gallons/day of blackwater via membrane bioreactors and UV disinfection for toilet flushing and irrigation, cutting potable water use by ~50% and easing sewer loads. [8]

- Rural Community in India: In Tamil Nadu, a village uses a constructed wetland system to treat 10,000 gallons/day of domestic wastewater, providing low-cost sanitation and irrigation water for local farms, demonstrating DWS applicability in developing regions. [9]

Researchers at the University of California, Riverside, note: "Water reuse can be a reliable, decentralized water source that has been viewed as a form of 'drought insurance' and offers reuse municipalities flexibility, resiliency, and independence to adapt to changing conditions." [11]

Challenges in Decentralized Management

- Regulations: Varying rules require early engagement. EPA guidelines set effluent limits (e.g., BOD < 30 mg/L, TSS < 30 mg/L for discharge), influencing treatment choices. [1]

- O&M: Dispersed and advanced units need expertise; use monitoring and education.

- Site Limits: Assess soil and groundwater.

- Perception: Educate on safety.

- Financing: Leverage multiple funding sources. [5]

- Nutrients: Plan for attenuation.

Best Practices for Success

- Planning: Site-specific designs integrating water cycles.

- Regulations: Collaborate for streamlined permits.

- O&M: Professional programs with remote tech.

- Engagement: Build trust via education.

- Financing: Use multiple funding sources.

- Technologies: Choose modular, adaptable units.

Conclusion: Building Resilient Water Systems

Localized treatment enhances sustainability and adaptability. Mastering DWS enables contributions to innovative solutions for water scarcity and environmental adaptability, integrating with centralized methods for robust infrastructure. As EPA resources state, "Decentralized wastewater treatment consists of a variety of approaches for collection, treatment, and dispersal/reuse of wastewater." [1]

Ready to Optimize Your Water Treatment?

Connect with Ecologix Systems today to discuss your specific needs and discover how our advanced solutions can enhance your operations.

Contact Our Experts NowGlossary

FAQ

Q1: How do decentralized systems remove pollutants like BOD and TSS?

A: DWS use a series of processes: primary treatment (e.g., clarifiers, DAFs, and septic tanks) removes

solids and some insoluble BOD; secondary treatment (e.g., aeration tanks, wetlands or SBRs) uses

microbes to break down organic matter, reducing BOD by 85–95% (see Wastewater Composition section);

advanced treatment (e.g., tertiary filtration, disinfection) polishes effluent for safe discharge

or reuse.

Q2: Why are decentralized systems important for sustainability?

A: DWS can reduce energy use (e.g., 0.1-0.3 kWh/m3 vs. 0.5-1 kWh/m3 for centralized systems), enable

water reuse (e.g., for irrigation), and recover resources like biogas from sludge. They support

sustainability by conserving water and energy, especially in water-scarce areas, aligning with goals

like efficient resource management.

Q3: How do decentralized systems handle variable wastewater flows?

A: DWS are designed for flexibility. One method is using systems that integrate an equalization

tank. Another might be sequencing batch reactors (SBRs) or wetlands that adapt to flow changes.

For example, an SBR processes wastewater in batches, adjusting cycle times for high or low flows

(e.g., 1,000-5,000 GPD), while wetlands use large surface areas to buffer flow variations, ensuring

consistent treatment.

Q4: How do engineers decide which treatment process to use in a DWS?

A: Engineers consider influent characteristics (e.g., BOD, TSS levels), site conditions (e.g., soil

type, space), and effluent goals (e.g., discharge to a river or reuse for irrigation). For example,

high-BOD industrial wastewater might need DAF and MBBR, while a rural home might use a septic tank

and wetland. Mass balance calculations help ensure pollutant removal meets standards like EPA's

BOD < 30 mg/L.

Q5: What role do environmental engineers play in DWS projects?

A: Environmental engineers design DWS, select technologies (e.g., MBBRs or MBRs for high-quality

reuse), monitor performance (e.g., testing BOD), and ensure compliance with regulations.

Keywords

Decentralized wastewater system, DWS, onsite wastewater treatment, constructed wetland, membrane bioreactor, AGFM, water reuse, produced water, biosolids, BOD, TSS, MBBR, nutrient removal, hydraulic loading rate, environmental engineering, sustainable water management.

Bibliography

- U.S. EPA. 2022 Guidelines for Water Reuse.

- U.S. EPA. New Homebuyer's Brochure and Guide to Septic Systems.

- U.S. EPA. A Plain English Guide to the EPA Part 503 Biosolids Rule.

- U.S. EPA. Septic Systems Reports, Regulations, Guidance, and Manuals.

- U.S. EPA. Clean Water State Revolving Fund (CWSRF) Factsheets.

- Ecologix Systems. Produced Water Treatment for Oil and Gas.

- Ecologix Systems. Bio-Clear Packaged Sewage Treatment.

- SFPUC. Onsite Water Reuse Program.

- Centre for Science and Environment. Decentralised Wastewater Treatment Systems in Tamil Nadu.

- Tchobanoglous, G., Stensel, H. D., Tsuchihashi, R., Burton, F. L., Abu-Orf, M., Bowden, G., & Pfrang, W. (2014). Wastewater Engineering: Treatment and Resource Recovery (5th ed.). McGraw-Hill Education.

- Eawag. Onsite Water Reuse Systems - San Francisco Case Study.