In any industrial wastewater treatment system, the effective removal of suspended solids is the cornerstone of success, profoundly impacting both operational efficiency and environmental compliance. In the primary treatment stage of a pulp and paper mill, removing these solids (primarily fibers, fillers, and other particulate matter) is crucial for several reasons. It protects downstream equipment from abrasion and fouling, significantly reduces the organic load (BOD and COD) that must be managed by more energy-intensive secondary processes, and is the first essential step toward any meaningful water reuse initiative. Failure to achieve high-efficiency solids removal at this initial stage results in higher costs, greater operational complexity, and a heavier burden on the entire treatment train.

The role of solids separation is equally critical, though functionally different, in secondary biological treatment. Here, the objective is not to remove raw influent solids, but to separate the purified water from the microbial biomass (activated sludge) that has consumed the dissolved pollutants. This separation is the final, vital step that determines the quality of the discharged effluent. An efficient secondary clarification process ensures that this valuable biomass is captured and returned to the aeration basin to continue its work, while guaranteeing that the final effluent is clear and meets stringent regulatory limits for Total Suspended Solids (TSS). A failure at this stage invalidates the entire biological process, leading to non-compliance and environmental harm.

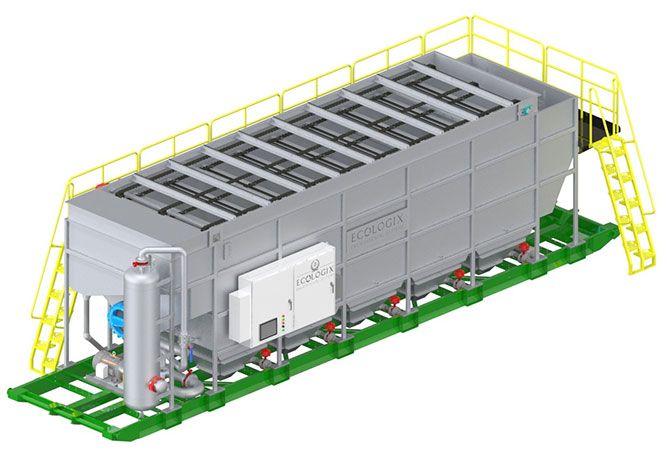

Advanced Engineering for Superior Primary Treatment

With this understanding, it's clear that the choice of solids separation technology is paramount. While facilities have long relied on large traveling bridge clarifiers, these aging systems are inefficient and costly to operate. The move to Dissolved Air Flotation (DAF) technology marks a significant step forward, but the true revolution lies in advanced DAF designs. Innovators like Ecologix Environmental Systems have engineered enhanced DAF systems that don't just replace clarifiers, they fundamentally optimize the entire wastewater treatment process by perfecting this critical function.

The effectiveness of a DAF system hinges on its ability to generate microscopic bubbles that attach to suspended solids and lift them to the surface. Enhanced systems perfect this core function. Ecologix, for example, utilizes a high-efficiency air dissolving system that creates a greater volume of finer micro-bubbles. This optimized bubble population, combined with specialized flotation zones, ensures maximum contact between air and solids. This is especially crucial for the low-density fibers in paper mill effluent, leading to superior TSS removal rates that often exceed what standard DAF technology can achieve, resulting in exceptionally clear effluent.

Redefining Footprint and Hydraulic Capacity

A key driver for replacing clarifiers is space savings, and this is where enhanced dissolved air floatation systems truly excel. Through intelligent hydraulic design and optimized internal flow patterns, advanced systems can handle significantly higher hydraulic and solids loading rates. This means a state-of-the-art system from a specialist like Ecologix can process more wastewater in an even smaller footprint than a conventional DAF system, let alone a sprawling concrete clarifier. This unlocks invaluable plant space for production upgrades and makes retrofitting easier than ever.

Maximizing Sludge Quality to Minimize Disposal Costs

Sludge handling and disposal represent a major operational expense. While any DAF system produces thicker sludge than a clarifier, enhanced systems take it a step further. They often incorporate proprietary features like integrated internal coalescing media and sludge thickening plates along with variable-speed skimmers. This design effectively provides a thicker floated sludge before it leaves the tank, producing a remarkably higher solids concentration cake, often achieving 4-6% solids consistency directly from the unit. This drastic reduction in water content slashes the burden on downstream equipment, cutting polymer use and generating a smaller volume of final cake for disposal.

Unlocking Efficiency with Intelligent Automation

Modern paper mills run on data and automation, and their wastewater systems should too. This is a key differentiator for enhanced DAF technology. Systems engineered by leaders like Ecologix are equipped with advanced PLC controls and sensor feedback loops. This allows for automated chemical dose adjustments based on real-time influent conditions and self-regulating air saturation. This level of smart control moves beyond manual operation, minimizing chemical waste, reducing the need for constant operator oversight, and ensuring consistently compliant effluent even with fluctuating production schedules.

Fortifying Biological Systems Against Upsets

In secondary treatment, a DAF system's ability to float biological solids is a game-changer for plants struggling with filamentous sludge bulking in conventional clarifiers. An enhanced DAF system provides an even more robust and reliable solids-liquid separation barrier. Its superior solids capture efficiency offers unmatched protection against process upsets, preventing solids carryover and safeguarding final effluent quality. For any facility with an activated sludge system, replacing an underperforming secondary clarifier with an advanced DAF system ensures a higher degree of plant security and compliance assurance.

The Compounded ROI of an Enhanced System

The decision to upgrade is ultimately an economic one. An enhanced DAF system delivers a powerful return on investment by compounding benefits across the board. The savings come not just from a smaller footprint and more intuitive automated controls, but from maximized fiber recovery, minimized chemical and polymer use through intelligent automation, and drastically reduced sludge handling and disposal fees. These amplified operational savings, coupled with improved water quality that facilitates internal reuse, create an undeniable business case for choosing a technologically superior system from an experienced provider like Ecologix Environmental Systems.

Ready to maximize your mill efficiency?

Contact Ecologix Environmental Systems to get the most out of your enhanced DAF system.

Contact Our Experts NowReferences

- U.S. Environmental Protection Agency (EPA). (1997). Profile of the Pulp and Paper Industry. Office of Enforcement and Compliance Assurance.

- Pokhrel, D., & Viraraghavan, T. (2004). Treatment of pulp and paper mill wastewater—a review. Science of The Total Environment, 333(1-3), 37-58. This journal article is often accessible through university library portals associated with .edu domains.

- World Bank Group. (2007). Environmental, Health, and Safety Guidelines for Pulp and Paper Mills.