Is your legacy API 421 oil water separator compliant with today's stringent regulations? Learn the limitations of 150 µm free oil removal and why secondary treatment (Adsorption, CPI, DAF) is essential to meet modern 15 ppm effluent goals.

Contact us today to learn more

We offer a free assessment of your wastewater treatment needs.

Contact UsWhat is the Core Effectiveness of an API 421 Separator?

The API oil-water separator, as defined by American Petroleum Institute Publication 421, is a robust, time-tested technology designed to serve as the primary treatment step for industrial oily wastewater in refineries and petrochemical plants.

Its core effectiveness is based on fundamental gravity separation principles (Stokes' Law):

The Stokes' Law Principle and the 150 µm Standard

The API 421 design is meticulously calculated to ensure sufficient detention time and laminar flow conditions for oil droplets to rise to the surface. Key design requirements encompass the following:

- Target Removal: The separator's design is optimized to effectively remove non-emulsified, free-floating oil droplets with a diameter of 150 micrometers (µm) or larger.

- Solids Removal: It effectively functions as a primary sedimentation basin, allowing heavy suspended solids to settle to the bottom for mechanical removal.

- Design Features: Compliance requires strict adherence to dimensional criteria, including a minimum length-to-width ratio of 5:1 and maintaining a low horizontal velocity (Vh) to prevent turbulence, which could break up oil droplets.

Effectiveness Summary: An API 421 separator is highly effective at removing gross amounts of oil (the large slugs and free-floating layers) before the wastewater moves on to secondary treatment.

The Critical Gap: Why API 421 Alone Fails Modern Compliance

While essential, a conventional API 421 gravity separator is often insufficient to achieve the low oil and grease discharge limits (typically 15 ppm or less) mandated by contemporary environmental permits.

The primary limitation of the API design is its inability to capture smaller oil droplets and emulsified oil.

| Compliance Challenge | Why the API Separator Fails |

|---|---|

| Fine Oil Droplets | The design only targets droplets ≥ 150 µm. Smaller, highly stable droplets (e.g., 20-60 µm) have a very slow rise rate and pass directly through. |

| Emulsified Oil | It cannot break mechanical or chemical emulsions. Oil stabilized by detergents, chemicals, or high-shear pumps remains suspended and passes through the separator. |

| Effluent Concentration | A standard API 421 unit typically produces an effluent of 30 ppm to 100 ppm of oil (depending on the type of oil and separator size), which is significantly higher than the standard 15 ppm limit for surface water discharge. |

| Flow & Temperature | Performance degrades rapidly with wastewater temperature drops (increasing viscosity) or flow surges (increasing turbulence), leading to non-compliance during unusual operational events. |

The Difference Between 150 µm and 15 ppm

The goal of 150 µm removal is a measure of droplet size, whereas the goal of 5 ppm (parts per million) is a measure of total oil concentration in the final effluent. Meeting the low concentration limit always requires removal of the small, hard-to-separate oil.

Beyond API 421: Required Secondary Treatment

For facilities to achieve and maintain full API 421 compliance while meeting strict 15 ppm discharge limits, the API gravity separator must be followed by advanced, high-efficiency secondary treatment technologies.

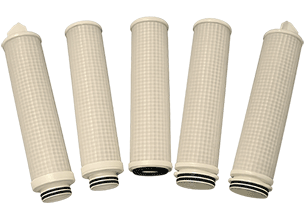

1. Polishing Media (Oil Adsorption)

- How it Works: Oil adsorbing media and filters like organoclay are exceptionally good at binding free oil, or oil droplets that have been mechanically emulsified. This type of media is often used as a “polishing” step and can bind a significant amount of its own weight in oils.

- Effectiveness: Organoclay can typically reduce free and mechanically emulsified oil and grease concentrations to non-detect, or low single digits, effectively meeting the 15 ppm regulatory requirement.

2. Coalescing Plate Interceptors (CPI/PPI)

- How it Works: These units contain packs of closely spaced, parallel or corrugated plates installed downstream of the API separator. The plates provide a vast surface area on which small oil droplets coalesce (merge) into larger, more buoyant droplets.

- Effectiveness: CPI/PPI units are highly effective at removing oil droplets down to 50 µm to 20 µm, turning the 150 µm effluent from the API unit into water that is much closer to final discharge quality.

3. Dissolved Air Flotation (DAF) and Emulsion Breaking

- How it Works: DAF systems are designed to remove both fine oil and remaining suspended solids. They inject air under pressure to create tiny bubbles that attach to oil/solids particles, dramatically increasing their buoyancy and causing them to float to the surface for skimming.

- Effectiveness: DAF, often paired with chemical pretreatment (to break chemical and mechanical emulsions), is the industry standard for polishing effluent to reliably meet the 15 ppm and no visible sheen regulatory requirements.

Partner with Ecologix Systems for Full Compliance

If your facility is relying on a legacy API 421 separator, Ecologix Environmental Systems provides the engineering and technology to bridge the gap between gross oil removal and final discharge compliance.

We specialize in API separators and retrofits, integrating advanced Oil Adsorption, CPI/PPI, and DAF technologies to guarantee your system meets modern environmental standards.

Contact us today to learn more

We offer a free assessment of your wastewater treatment needs.

Contact Us