Summary

Here we will dive into how we typically treat emulsified oils in wastewater, emphasizing chemical demulsification strategies integrated with dissolved air flotation (DAF) for removal. We cover coagulants, flocculants, reaction kinetics, and physical separation principles, supported by mathematical models, to achieve low levels of fats, oils, and greases (FOG) and total suspended solids (TSS) in effluents from various industries.

Table of Contents

Introduction

Emulsified oils in wastewater present complex treatment challenges owing to their fine droplet dispersion, stabilized by surfactants, mechanical shear, or natural emulsifiers. These emulsions frequently originate from industrial operations including petroleum refining, metalworking, dairy processing (where milk fats contribute to very high FOG loads), and food and beverage processing (involving vegetable oils and animal fats). Effective remediation entails chemical demulsification to destabilize the oil-water interface, followed by physical separation to extract aggregated contaminants. This methodology reduces FOG and TSS to compliant levels, often below 15 mg/L for oil content [1]. Critical components will include either chemical reaction tanks or flocculation tubes, preparing the stream for removal via dissolved air flotation.

Process Overview

Treatment of emulsified oils proceeds through sequential stages: chemical demulsification, flocculation, and physical separation. In the chemical phase, demulsifiers and coagulants are introduced to neutralize surface charges on oil droplets, promoting coalescence. Flocculation ensues, where polymers facilitate the bridging of destabilized particles into macro-flocs. Physical separation, via DAF, leverages microbubbles to buoy flocs containing FOG suspended solids for skimming.

A foundational principle is Stokes' Law for particle settling or rising velocity:

Where is terminal velocity (m/s), and are particle and fluid densities (kg/m3), is gravity (9.81 m/s2), is particle radius (), and is fluid viscosity (Pa⋅s). Chemical treatment enlarges , dramatically accelerating separation [2].

Demulsification efficiency can be quantified using the demulsification ratio:

This metric evaluates phase separation post-treatment [3].

Chemical Treatment Details

Demulsification relies on agents that disrupt the oil-water interface by adsorption, charge neutralization, or hydrophile-lipophile balance alteration. Inorganic coagulants include polyaluminum ferric chloride (PAFC), polyaluminum chloride (PAC; often formulated as [Al2(OH)nCl6-n]m [25]), polysilicate aluminum ferric sulfate (PSAFS), polyferric sulfate (PFS; [Fe2(OH)n(SO4)3-n/2]m [27]), aluminum sulfate (alum; Al2(SO4)3·14H2O), ferric chloride (FeCl3·6H2O), ferric sulfate (Fe2(SO4)3·9H2O), ferrous sulfate (FeSO4·7H2O), sodium aluminate (Na2Al2O4), and calcium hydroxide (lime; Ca(OH)2) [14]. Organic flocculants encompass polyacrylamide (PAM; (C3H5NO)n), natural alternatives like chitosan ((C6H11NO4)n), anionic polymers (e.g., polyacrylic acid derivatives), cationic polymers (e.g., polydiallyldimethylammonium chloride, PDADMAC; (C8H16ClN)n), and nonionic polymers (e.g., polyethylene oxide, PEO; (C2H4O)n) [15]. For pH adjustment, sulfuric acid (H2SO4) lowers pH to destabilize acidic emulsions, while sodium hydroxide (NaOH) elevates pH to precipitate solids in alkaline conditions [5].

Specialized demulsifiers for stable emulsions include quaternary ammonium compounds such as cetyltrimethylammonium bromide (CTAB; C19H42BrN or C16H33N(CH3)3Br), trioctylmethylammonium chloride (TOMAC; [CH3(CH2)7]3N(CH3)Cl), and ionic liquids like 1-dodecyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide ([C12mim][NTf2]; C16H23F6N3O4S2) or 1-octyl-3-methylimidazolium hexafluorophosphate ([C8mim][PF6]; C12H23F6N2P) [16]. These amphiphilic agents reduce interfacial tension, with CTAB achieving up to 90% demulsification efficiency in water-in-oil emulsions at 300-700 mg/L dosages [16]. Ionic liquids, often with hydrophobic tails, offer tunable properties for FOG-heavy streams, yielding 90-100% separation at low concentrations (100-3500 ppm) but may incur higher costs [16].

Coagulation mechanics involve charge neutralization, where cationic metal hydroxides from coagulants (e.g., Al3+ from PAC or Fe3+ from FeCl3) adsorb onto anionic oil droplets. For instance, PAFC at 300 mg/L, paired with PAM at 30 mg/L, reduces oil from 3000-5000 mg/L to <15 mg/L, with optimal pH 6.5-6.9 to avoid restabilization [1]. Kinetics follow second-order aggregation models, approximated by:

where is particle concentration, is time, and is the aggregation rate constant, influenced by mixing intensity and zeta potential [6].

Advanced optimization employs the Hydrophilic-Lipophilic Deviation - Net Average Curvature (HLD-NAC) model for surfactant-based systems. The HLD equation is:

with terms for salinity ((s)), oil hydrophobicity (EACN), alcohol effects ((A)), temperature deviation (Δ), and surfactant characteristic (Cc). Optimal demulsification occurs at HLD ≈ 0 (Winsor III phase), minimizing interfacial tension [7]. NAC extends this with net curvature:

and average curvature bounded by characteristic length ξ, aiding in demulsifier formulation for dairy or food emulsions rich in FOG [7].

Flocculation in serpentine tubes involves the equivalent of rapid mixing (350-800 rpm, 1-5 min) for dispersion, then slow mixing (50-150 rpm, 10 min) for floc growth. Thermal enhancement (45-120°F) accelerates kinetics, particularly for viscous FOG-laden streams from food and beverage sources [6]. Organoclays, modified bentonites, serve as adsorbents for residual emulsions, outperforming activated carbon by a factor of seven in polishing steps [8].

The table below compares coagulants at 500 mg/L dosage:

| Coagulant | Demulsification Order | Advantages | Disadvantages |

|---|---|---|---|

| PAFC | Highest | Rapid dissolution, large dense flocs, short floating time, wide pH range, effective at low dosages. | Less effective at very low doses, potential for fine flocs at high doses, requires higher dosages than PAC in some applications. |

| PAC | High | Rapid dissolution, stable performance, better than simple inorganic salts, large dense flocs, lower optimal dosages. | High dosages can be costly, deliquescent and hard to preserve, slow flotation speed. |

| PSAFS | Medium | Rapid dissolution, large dense flocs, fast floating speed, low dosage effective. | Difficult to store, deliquescent, solution may blacken, leaves small flocs. |

| Alum | Medium | Inexpensive, widely available, dense flocs, easy to use if dosed properly. | Limited pH range, requires large amounts for dirty water, produces significant gelatinous sludge, slow flotation. |

| PFS | Low | Suitable for low temperatures, rapid flocculation, easy separation, wide applicable range. | Leaves fine flocs in effluent, less effective overall, poor removal of oil. |

| FeCl3 | Variable (high in some oily wastes) | No pH requirement, broad range effectiveness, high removal for TSS/FOG (e.g., 97% oil/grease in combinations). | Highly corrosive (needs special equipment), price fluctuations, significant pH drop. |

| Chitosan | Variable | Eco-friendly/natural, low dosage needed, biodegradable sludge, high efficiency for turbidity/TSS, synergistic with PAC. | pH/solubility dependent, dosage sensitive (overdosing causes restabilization), scalability challenges. |

Physical Removal Techniques

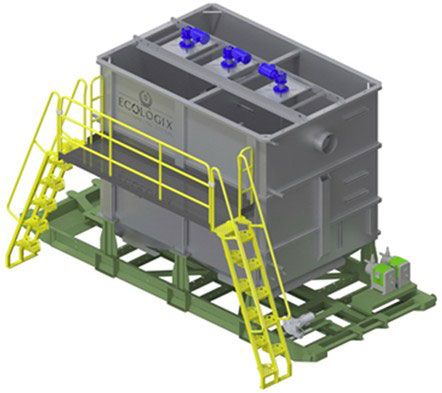

After chemical treatment, physical removal employs dissolved air flotation (DAF) systems, where pressurized air is dissolved in water and released to form microbubbles (30-120 μm) that attach to flocs, increasing buoyancy [10]. In a typical DAF unit, wastewater from the flocculation tubes enters the flotation tank, with bubble flow rates optimized for efficient collision [11].

A typical system includes the wastewater inlet, air saturation tank (pressurized at 4-6 atm), release into the flotation basin where bubbles form and lift flocs to the surface for skimming and clarified effluent outlet. Sludge is removed via flights [12].

Other methods include organoclay filtration for polishing, where modified bentonite adsorbs residual oil at rates seven times faster than activated carbon [13]. Gravity separators like API or CPI are used for preliminary free oil removal but are less effective for emulsions without prior chemical treatment. DAF excels in removing FOG and TSS, achieving >95% efficiency even in exceedingly tough to treat streams such as dairy wastewater [10].

Challenges in Treatment

Variability in emulsion stability from surfactants or FOG content leads to inconsistent removal. Overdosing causes charge reversal and restabilization, while pH fluctuations demand tight control. High viscosity in food and beverage wastes increases energy for mixing, and TSS buildup complicates sludge handling [18].

Solutions and Optimizations

Jar testing simulates conditions to refine dosages, incorporating HLD-NAC for demulsifier design. Multi-coagulant blends (e.g., PAFC + chitosan) enhance floc robustness for FOG-heavy streams. Real-time monitoring of TSS, FOG, and turbidity via sensors help ensure adaptive control [19].

Conclusion

Advanced chemical demulsification, bolstered by models like HLD-NAC and integrated with dissolved air flotation treatment, offers a sophisticated approach to emulsified oil removal in wastewater. By leveraging detailed chemistry, mathematics, and engineering, this framework addresses FOG and TSS in diverse industries like dairy and food and beverage, enabling efficient, scalable treatment.

Glossary of Terms

- Alum: Aluminum Sulfate - Al2(SO4)3·14H2O, a primary coagulant for charge neutralization.

- API: American Petroleum Institute gravity separator - A tank designed for oil-water separation based on density differences.

- BOD: Biological Oxygen Demand - A measure of the amount of oxygen required by microorganisms to decompose organic matter in water.

- Ca(OH)2: Calcium Hydroxide (Lime) - A coagulant used for pH adjustment and precipitation.

- CaO: Calcium Oxide (Quicklime) - A coagulant aid for alkalinity control.

- COD: Chemical Oxygen Demand - A measure of the oxygen required to chemically oxidize organic and inorganic matter in water.

- Coagulant: A chemical agent that neutralizes charges on particles to promote aggregation.

- CPI: Corrugated Plate Interceptor - An enhanced gravity separator using inclined plates to increase oil droplet coalescence.

- CTAB: Cetyltrimethylammonium Bromide - C19H42BrN, a quaternary ammonium demulsifier for emulsion breaking.

- DAF: Dissolved Air Flotation - A physical separation process using microbubbles to float contaminants.

- Demulsification: The process of breaking stable oil-water emulsions.

- Demulsifier: A substance that destabilizes emulsions by disrupting the interface between oil and water.

- Effluent: The treated wastewater discharged from a treatment process.

- Emulsion: A stable mixture of two immiscible liquids, such as oil droplets and water.

- FeCl3·6H2O: Ferric Chloride - A primary coagulant for high FOG wastewater.

- FeSO4·7H2O: Ferrous Sulfate - A primary coagulant used in oxidation-coagulation processes.

- Fe2(SO4)3·9H2O: Ferric Sulfate - A primary coagulant for turbidity and oil removal.

- Flocculant: A polymer that bridges aggregated particles to form larger flocs.

- Flocculation Tubes: Pipe-like structures for controlled mixing to form flocs.

- FOG: Fats, Oils, and Greases - Hydrophobic contaminants common in food-related wastewater.

- H2SO4: Sulfuric Acid - Used for pH adjustment in demulsification.

- [C12mim][NTf2]: 1-Dodecyl-3-methylimidazolium Bis(trifluoromethylsulfonyl)imide - C16H23F6N3O4S2, an ionic liquid demulsifier.

- Na2Al2O4: Sodium Aluminate - A coagulant for alkalinity and precipitation.

- Na2SiO3: Sodium Silicate - A coagulant aid for floc strengthening.

- NaOH: Sodium Hydroxide - Used for pH elevation in chemical treatment.

- PAC: Polyaluminum Chloride - [Al2(OH)nCl6-n]m, a coagulant for emulsion destabilization [25].

- PAM: Polyacrylamide - (C3H5NO)n, a flocculant that bridges particles into larger aggregates.

- PAFC: Polyaluminum Ferric Chloride - A coagulant used for charge neutralization in emulsions.

- PDADMAC: Polydiallyldimethylammonium Chloride - (C8H16ClN)n, a cationic polymer flocculant.

- PEO: Polyethylene Oxide - (C2H4O)n, a nonionic polymer flocculant.

- pH: A measure of the acidity or alkalinity of a solution on a scale from 0 to 14.

- PFS: Polyferric Sulfate - [Fe2(OH)n(SO4)3-n/2]m, an iron-based coagulant for wastewater treatment [27].

- PSAFS: Polysilicate Aluminum Ferric Sulfate - A composite coagulant effective at low temperatures.

- TOMAC: Trioctylmethylammonium Chloride - [CH3(CH2)7]3N(CH3)Cl, a demulsifier for heavy oil emulsions.

- TSS: Total Suspended Solids - The dry-weight of particles trapped by a filter, including organic and inorganic matter.

- Turbidity: A measure of the cloudiness or haziness of water caused by suspended particles.

FAQ

- What is the role of pH in chemical treatment? pH influences coagulant hydrolysis and emulsion stability; optimal ranges prevent restabilization.

- How does DAF improve over gravity separation? Microbubbles enhance buoyancy for finer particles, effectively removing FOG and TSS.

- What are common demulsifiers? Inorganic coagulants like PAFC or FeCl3, organic polymers like PAM, quaternary salts like CTAB, and ionic liquids like [C12mim][NTf2].

- Why use flocculation tubes? They are used for a multi-stage mixing process that includes both rapid mixing for chemical dispersion and slower mixing for floc formation. The purpose is to build large, easily removable flocs. Floc tubes are also cheaper than chemical reaction tanks, so if the chemical reaction time is relatively low, we can design in floc tubes.

- How do I test for treatment efficacy? Jar tests and demulsification ratio calculations will help you optimize your chemical dosages.

Bibliography

- Effective treatment of emulsified oil wastewater by the coagulation–flotation process

- Treatment of oil-water emulsion through coagulation-flocculation and sedimentation using waterworks sludge as a green agent

- How can I calculate the demulsification ratio of water-based Polymer emulsions?

- An eco-friendly approach to separate emulsified oil from water using all natural materials of chitosan and beach sand

- How to Remove Oil from Water: Wastewater Management Techniques

- Feasibility investigation of oily wastewater treatment by combination of zinc and PAM in coagulation/flocculation

- Design of industrial wastewater demulsifier by HLD-NAC model

- How to Remove Emulsified Oil from Wastewater with Organoclays

- Insights into the control mechanism of different coagulation pretreatment on ultrafiltration membrane fouling for oily wastewater treatment

- ResearchGate: Treatment of Oily Wastewater Using Dissolved Air Flotation Technique

- ResearchGate: Mathematical model of dissolved air flotation (DAF) based on impulse conservation law

- ResearchGate: Schematic diagram of the Dissolved Air Flotation system (DAFs)

- How to Remove Contaminants in Water with Organoclays

- MECC: Coagulant Chemicals in Water Treatment

- HPI: Coagulants and Flocculants in Wastewater Treatment: Function, Synergy, and Advancements

- Application of Ionic Liquids for Chemical Demulsification: A Review

- A critical review of the development and demulsification processes applied for oil recovery from oil in water emulsions

- Oily Wastewater Treatment: Methods, Challenges, and Trends

- Evaluating dissolved air flotation for oil/water separation using a hybridized coagulant of ferric chloride and chitosan

- Alum and Ferric Chloride: Pros, Cons, and Substitutes

- Synergy Between Low-Cost Chitosan and Polyaluminum Chloride (PAC) Improves the Flocculation Process for River Water Treatment

- Wastewater Treatment Using Alum, the Combinations of Alum-Ferric Chloride, Alum-Chitosan, Alum-Zeolite and Alum- Moringa Oleifera as Adsorbent and Coagulant

- Effective treatment of emulsified oil wastewater by the coagulation-flotation process

- Comparative study of Poly Aluminum Ferric and Poly Aluminum Chloride Performance for Turbidity Removal from River Water

- Poly Aluminum Chloride (PAC)

- A critical review of the development and demulsification processes applied for oil recovery from oil in water emulsions

- Polymeric Ferric Sulfate For Waste & Drinking Water

Have a project you would like to discuss?

Contact Ecologix Environmental Systems today to learn more about our engineered solutions.

Contact Us