The pulp and paper industry, a cornerstone of global communication and commerce, faces an immense environmental responsibility: managing its wastewater. Effluent from paper mills is a complex cocktail of organic matter, chemicals, and suspended solids, making it one of the most challenging industrial streams to treat. Fortunately, Moving Bed Biofilm Reactor (MBBR) technology offers a robust, efficient, and compact solution tailored for this demanding environment.

The Challenge of Pulp & Paper Effluent

Wastewater from pulp and paper manufacturing is notoriously difficult to manage due to several factors:

- Extremely High COD & BOD: Caused by dissolved wood components, primarily lignin and cellulose fibers.

- Recalcitrant Compounds: Lignins and tannins are complex organic polymers that are resistant to conventional biological degradation.

- Color and Toxicity: Effluent is often darkly colored and can contain chlorinated organic compounds (AOX) from bleaching processes, which are toxic.

- High Suspended Solids: Fine fibers and fillers require effective removal to prevent system clogging and ensure compliance.

Traditional treatment methods like activated sludge systems often require massive footprints and can be easily upset by the toxicity and variability of the influent, leading to inconsistent performance.

MBBR: A Superior Biological Solution

MBBR technology excels where other systems falter. By cultivating a specialized, highly resilient biofilm on thousands of free-floating media carriers, MBBR systems create a concentrated biomass that is perfectly suited to break down the tough pollutants in paper mill wastewater.

The vast, protected surface area of the media allows for the development of slow-growing, specialized microorganisms that are highly effective at degrading complex organic molecules like lignin. This results in a system that is not only efficient but also incredibly stable.

Why MBBR is the Right Choice for Pulp & Paper

Superior COD & BOD Removal

The concentrated biomass in an MBBR achieves significantly higher removal rates for COD and BOD compared to conventional systems, ensuring compliance with the strictest discharge limits.

Resilience to Toxicity

The robust, attached-growth biofilm is highly resistant to toxic shock loads and variations in influent quality, providing reliable and consistent treatment performance day in and day out.

Effective Color Removal

The specialized microorganisms in the biofilm are adept at breaking down the complex molecules that cause color in the effluent, leading to a clearer, higher-quality discharge.

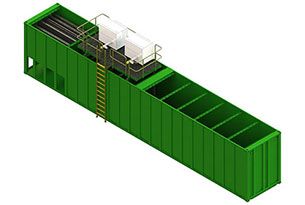

Small Footprint & Easy Retrofit

MBBRs treat more waste in less space. This makes them ideal for upgrading existing treatment plants or for new installations where space is a premium.

Meeting the Future of Sustainable Papermaking

As environmental regulations become more stringent, the pulp and paper industry must adopt more advanced and reliable wastewater treatment technologies. MBBR provides a cost-effective, operationally simple, and highly efficient solution that meets the challenges of today and tomorrow.

By integrating MBBR technology, pulp and paper mills can achieve superior effluent quality, reduce their environmental footprint, and ensure long-term operational sustainability.