Summary

Ecologix Environmental Systems offers a diverse range of oil/water separation technologies designed to address everything from massive industrial runoff to fine hydrocarbon sheens. A key distinction in our lineup is the use of high-efficiency coalescing media and our proprietary MCM-830 OrganoClay for polishing and emulsified oil removal.

The following article outlines the Ecologix separator fleet, their applications, and the unique benefits of our adsorption media.

A Guide to Ecologix Oil/Water Separators

In industrial wastewater treatment, one of the primary challenges is removing hydrocarbons to meet strict environmental discharge permits. Ecologix Environmental Systems provides a "treatment train" approach, offering solutions that range from primary gravity separation to advanced molecular adsorption.

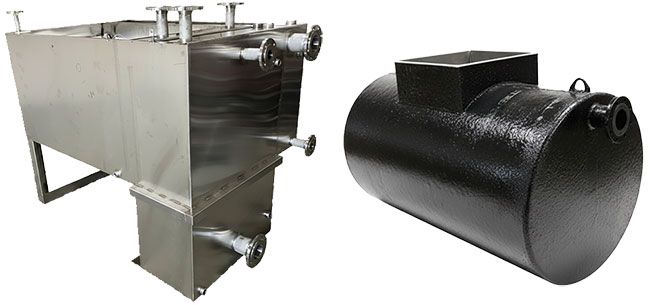

1. Above-Ground Oil/Water Separators (AGS/AGM Series)

These are the workhorses of the Ecologix line, utilizing parallel corrugated plate technology to accelerate the natural rise of oil.

- How it works: Wastewater enters a chamber where flow is slowed. As it passes through the plate packs, small oil droplets are forced to collide and "coalesce" into larger, more buoyant drops that rise to the surface for skimming.

- Best Use Situations: Facilities with high water tables (where digging is impossible), easy access and maintenance is a priority, or leased spaces where equipment must be mobile.

- Advantages: 40-60% lower installation cost than buried units; easy visual inspection; no "confined space" entry required for maintenance.

- Disadvantages: Occupies valuable floor space; requires insulation or heaters in outdoor freezing climates.

- Industries: Auto body shops, repair garages, manufacturing plants, and truck wash centers.

- Cost & Simplicity: Low-to-moderate cost; very simple to operate with no moving parts or power consumption.

2. Below-Ground Oil/Water Separators (HQB Series)

Designed for permanent installations, these cylindrical gravity displacement tanks are built to UL-58 and UL-1746 standards.

- Best Situations: Urban sites with limited floor space; stormwater management; and facilities requiring a "clean" look.

- Advantages: Zero above-ground footprint; naturally insulated by the soil (perfect for cold climates); handles large-volume stormwater flows by gravity.

- Disadvantages: Higher upfront cost (2-3x) due to excavation; maintenance requires vacuum trucks; restricted access for inspections.

- Industries: Airports, bus depots, fuel terminals, and large-scale industrial parks.

- Cost & Simplicity: Higher capital expenditure; maintenance is more complex but infrequent.

3. Marine-Grade Separators (BORS - Bilge Oil Removal Systems)

These systems are specifically engineered for the rigors of maritime environments and are US Coast Guard and IMO certified.

- Best Situations: Onboard ships, offshore platforms, or mobile truck-mounted applications where the unit must operate while in motion.

- Advantages: Compact footprint; stable performance even with 30-degree tilts or heavy vibration; no consumables/filters required for the standard unit.

- Industries: Shipping, maritime logistics, and offshore oil/gas.

- Simplicity: High; often features automated self-monitoring and self-priming capabilities.

4. Specialized & Secondary Treatment

For applications that go beyond simple "free oil" removal, Ecologix offers:

- SkimLoop™: Best for removing floating oils and solids from industrial fluids (like coolants) to extend fluid life.

- Gun Barrel Separators: Specialized for the oil and gas sector where oil volume exceeds water volume in produced fluids.

MCM-830 OrganoClay Adsorption Media

Standard separators are excellent at removing free oil (droplets >20 microns), but they often struggle with emulsified or dissolved hydrocarbons. This is where the MCM-830 adsorption media becomes essential.

What is MCM-830?

MCM-830 is a modified quaternary amine-treated bentonite clay. Unlike traditional filters that act as a "sieve," MCM-830 acts like a chemical magnet. It is organophilic (oil-loving), meaning it attracts and chemically binds hydrocarbons to its molecular structure.

Key Characteristics for Customers:

- Superior Efficiency: MCM-830 removes oil at 700% the rate of activated carbon.

- High Capacity: It can capture 50-60% of its own weight in oil and grease before needing replacement.

- Polishing Capabilities: It can reduce Total Petroleum Hydrocarbons (TPH) and Benzene, Toluene, Ethylbenzene, and Xylene (BTEX) to non-detectable levels—often required for municipal sewer discharge or environmental release.

- Simplicity of Use: Available in granular form for use in pressure vessels (like the AHP-55 Liquid Phase Vessels) or as MCM Cartridge Filters for "plug-and-play" replacement in standard filter housings.

- Cost Comparison: While the media has an upfront cost, it significantly reduces total operating costs. By using MCM-830 as a pre-filter to downstream filtration, you prevent "blinding" (clogging) of expensive activated carbon or membrane systems, extending their life by up to 5 times.

When to use MCM-830?

If your facility is facing fines for "oil sheen" or "dissolved organics," or if your wastewater contains mechanically emulsified oils from high-pressure washing, adding an MCM-830 polishing vessel after your primary separator is the most cost-effective way to achieve compliance.

Summary Table

| Technology | Best For | Main Advantage | Cost Level |

|---|---|---|---|

| Above-Ground (AGS) | General Industrial | Low install cost; easy maintenance | $ |

| Below-Ground (HQB) | Stormwater / Urban | No footprint; freeze protection | $$$ |

| BORS (Marine) | Ships / Platforms | Works in motion; USCG Certified | $$ |

| MCM-830 Media | Polishing / Sheen | 7x more effective than carbon | $ (Consumable) |

By combining robust mechanical separation with the chemical power of MCM-830, Ecologix provides a scalable solution for any oily wastewater challenge.

Specialized Oil Filters

While the gravity-based separators mentioned previously handle the heavy lifting, Ecologix offers two specialized "polishing" technologies for ultra-fine filtration: OilFree Filters and MCM OrganoClay Filters.

The main difference lies in their chemistry: OilFree is a high-speed polymer-based "free-oil" magnet, while MCM is a high-capacity clay-based "emulsified-oil" specialist.

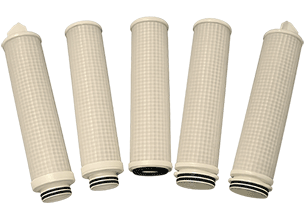

1. OilFree™ Filter Cartridges

The OilFree series uses patented polymeric technology specifically designed to remove hydrocarbons from water instantly without the pressure buildup common in traditional filters.

- How it works: Hydrocarbons are immobilized and permanently bonded to the polymer surface upon contact.

- Best Situations: High-flow polishing (up to 5,000 GPM) and applications sensitive to pressure drops. It is the "gold standard" for removing visible sheens.

- Advantages: * Near-Zero Pressure Drop: Saturated cartridges maintain

a pressure drop of less than 1 psi.

- Versatility: Removes BTEX, PCBs, solvents, and organically bound metals.

- Efficiency: Removes Total Petroleum Hydrocarbons (TPH) to below detectable limits (99.9%+ efficiency).

- Disadvantages: Primarily designed for free and dispersed oil; heavy mechanical emulsions may shorten the cartridge life. Water must be free of solids.

- Industries: Marine bilge water, aircraft wash racks, and groundwater remediation.

2. MCM OrganoClay Filters

MCM filters are engineered for more difficult wastewater that contains emulsified and dissolved hydrocarbons that standard separators simply cannot catch.

- How it works: These filters use a powdered version of the MCM-830P OrganoClay. Unlike other clays, this is 100% non-swelling. It doesn't just trap oil—it adsorbs it into its molecular structure.

- Best Situations: Removing mechanically emulsified oils (often caused by high-pressure pumps) and chemically emulsified oils and organics.

- Advantages: * High Capacity: Can absorb 50-60% of its weight in

hydrocarbons.

- Longer Life: Because it is non-swelling, it doesn't "blind" (clog) the filter cartridge, allowing it to last 2-3x longer than competitive clay/anthracite blends.

- Heavy Hitter: Removes oil at 700% the rate of activated carbon.

- Disadvantages: Requires a 5-micron pre-filter to prevent "solids blinding" (the media should only see oil, not dirt/silt).

- Industries: Produced water in Oil & Gas, creosote treatment, and complex industrial manufacturing.

Direct Comparison: Which Filter Do You Need?

| Feature | OilFree™ Cartridges | MCM OrganoClay Filters |

|---|---|---|

| Primary Goal | Sheen & Free Hydrocarbon removal | Emulsified & Dissolved Oil removal |

| Speed | Instant bonding (high flow) | High-contact adsorption requires low flow |

| Pressure Drop | Ultra-low (<1 psi) | Standard (increases as saturated) |

| Top Strength | Removing "Large Slugs" of oil | Removing trace dissolved organics |

| Specialty | Standard hydrocarbons, PCBs, and BTEX | 7x more effective than carbon |

Simplicity and Cost

- Simplicity: Both are "Plug-and-Play." They are typically housed in stainless steel vessels with simple swing-bolt lids for easy swap-outs.

- Cost: Both represent a consumable cost but offer a massive ROI by protecting downstream equipment. Using these as a "pre-polishing" step before Granular Activated Carbon (GAC) can extend the life of the GAC by up to 500%, significantly lowering your long-term O&M budget.

Contact us today to learn more

Connect with Ecologix Systems today to discuss your project.

Contact us today