In the demanding world of industrial waste management, volume reduction is the name of the game. For facility managers dealing with landfill leachate, produced water, or RO reject, the goal is simple: reduce liquid volume to minimize disposal costs.

While traditional electric evaporators have long been a standard choice, a more robust technology is rapidly gaining ground. Submerged Combustion Evaporators (SCE), exemplified by systems like Ecologix's EvapoDry, are rewriting the rules of efficiency, offering a "zero-fouling" solution that operates where other systems fail.

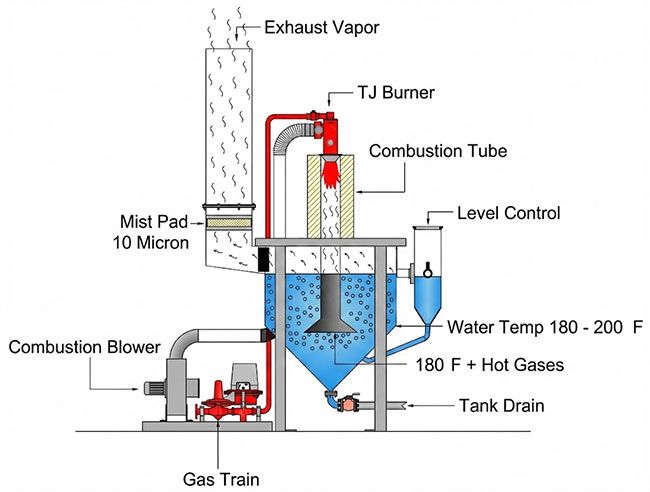

The defining characteristic of an SCE system is right in the name: the combustion happens inside the liquid. Unlike traditional systems that rely on a metal heat exchanger to transfer energy, an SCE system forces hot combustion gases directly into the wastewater through a submerged burner tube. This creates a turbulent, bubbling bath where the heat transfer is instantaneous and nearly 100% efficient. Because there is no metal barrier between the heat source and the water, the system bypasses the primary weakness of electric evaporators: thermal resistance.

The Efficiency Edge: Conquering the Scaling Problem

The most significant advantage of submerged combustion over electric evaporators is its immunity to scaling. In an electric unit, heating elements or heat exchangers are submerged in the waste. As water evaporates, minerals and solids precipitate out, forming a hard, insulating crust (scale) on the heating surfaces. This scale acts like a blanket, forcing the electric system to work significantly harder to transfer the same amount of heat, causing energy costs to skyrocket and efficiency to plummet over time.

Submerged combustion systems like the EvapoDry eliminate this issue entirely. The "heat transfer surface" in an SCE is the surface of millions of gas bubbles rising through the liquid. You cannot scale a bubble. Consequently, the thermal efficiency remains consistently high (often exceeding 95%) regardless of how much solid material accumulates in the tank. This "zero-fouling" heat transfer mechanism means the system runs at peak performance on day 1,000 just as it did on day 1. [1]

Lower Boiling Points and "Partial Vacuum" Thermodynamics

Beyond simple heat transfer, these systems utilize advanced thermodynamics to maximize energy usage. By pulling a partial vacuum on the evaporation chamber and utilizing the partial pressure physics of the combustion gases, units like the EvapoDry can evaporate water at significantly lower temperatures—typically around 180°F to 186°F (82°C - 85°C)—rather than the standard 212°F (100°C).

This ability to boil water at a lower set point changes the economic equation of evaporation. It requires less sensible heat to bring the wastewater to its boiling point, resulting in direct fuel savings. Furthermore, operating at these lower temperatures prevents the thermal breakdown of organic solids and prevents heavy metals from vaporizing into the air stream, a common environmental headache with high-temperature boiling. [2]

Unmatched Fuel Flexibility

While electric evaporators are tethered to the grid—often incurring high demand charges—submerged combustion evaporators offer versatile fuel adaptability. They are designed to run on standard fuel sources like propane and natural gas, but their rugged burners can also be tuned for alternative fuels such as methane, butane, and even landfill gas (LFG). This is a game-changer for remote sites like landfills or oil fields, where the facility can often run the evaporator using the very waste gas they are already flaring, effectively turning a waste product into free fuel for liquid reduction.

Built for the Toughest Environments

Finally, the value of simplicity cannot be overstated. Industrial waste streams are harsh, corrosive, and abrasive. The EvapoDry evaporator is built with this in mind, often featuring self-cleaning designs. For instance, as solids precipitate out of the solution, they settle into a cone-bottom tank where an automated auger and flush system continuously removes the sludge. This "hands-off" maintenance approach contrasts sharply with electric units that require frequent shutdowns for acid cleaning or sandblasting to remove scale. Whether deployed in a remote oil field or a bustling industrial plant, the submerged combustion evaporator offers a level of durability and uptime that fragile electric elements simply cannot match. [3]

Ready to Eliminate Wastewater Headaches?

In an industry where downtime is costly and efficiency is paramount, sticking with fragile, scale-prone electric evaporators is a risk you don't need to take. If your facility demands a solution that is as rugged as the environment it operates in, one that embraces fuel flexibility, maximizes thermal efficiency through smart thermodynamics, and refuses to let scaling slow you down, then it's time to rethink your evaporation strategy.

Contact Ecologix today to discuss your project.

Ecologix Environmental Systems is ready to help you transition to a more robust, cost-effective wastewater solution.

Contact Us