Summary

Effective industrial wastewater treatment is a critical component of modern manufacturing and processing, ensuring that water discharged from industrial facilities meets stringent regulatory standards and protects the environment [1]. Because every industrial process produces a unique "fingerprint" of contaminants, treatment systems must be highly customized. A comprehensive treatment plant often employs a "treatment train" approach, moving water through sequential stages: primary physical/chemical treatment, secondary biological treatment, and tertiary polishing [2]. Companies like Ecologix Environmental Systems specialize in integrating these stages into complete, turn-key solutions tailored to the specific flow rates and contaminant loads of a facility.

Table of Contents

1. Primary: Physical/Chemical Treatment

The first line of defense in many industrial systems is Physical/Chemical (Phys/Chem) treatment. This stage is primarily designed to remove suspended solids (TSS), insoluble biochemical oxygen demand (BOD), and fats, oils, and grease (FOG). Before the water can be effectively clarified, it often undergoes chemical conditioning in Chemical Reaction Tanks or Floc Tubes, such as those offered by Ecologix. Here, coagulants and flocculants are added to neutralize the electrical charges of particles, causing them to clump together into larger "flocs" that are easier to separate from the water.

2. Dissolved Air Flotation (DAF)

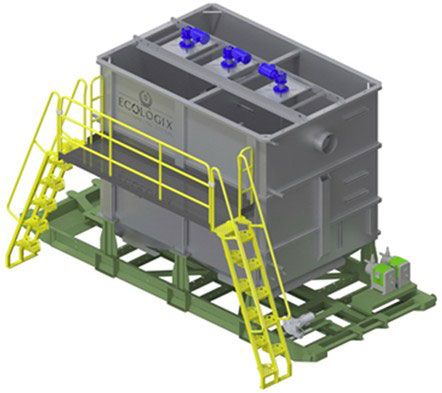

For the removal of these flocs, particularly when dealing with fats, oils, and grease (FOG) and lighter suspended solids, Dissolved Air Flotation (DAF) is the industry standard [3]. Ecologix's Enhanced DAF (E-DAF) systems are specifically engineered for this purpose. The DAF process introduces microscopic air bubbles into the wastewater, which attach to the suspended solids and oils, floating them to the surface where they form a sludge blanket that is skimmed off. This is highly effective for food and beverage facilities, slaughterhouses, and oil and gas operations where high concentrations of oil and solids are common.

3. Oil Water Separators

When the primary contaminant is free oil, such as in automotive or petrochemical applications, specialized Oil Water Separators (OWS) are utilized prior to or in place of other primary treatments. Ecologix provides configurations including:

These systems use gravity and coalescing media to separate oil droplets from water, effectively removing free-floating hydrocarbons before the water moves to sensitive downstream processes.

4. Biological Treatment

While Phys/Chem treatment removes solids, it cannot effectively remove soluble organic matter—sugars, alcohols, and proteins dissolved in the water. This requires Biological Treatment, where microorganisms are used to consume the organic waste.

Moving Bed Biofilm Reactor (MBBR)

A leading technology in this space is the MBBR [4]. Ecologix's MBBR systems utilize specialized Eco Chips, which are high-surface-area media carriers that float in the aeration tanks. These chips have the highest usable surface area, and host a robust biofilm of bacteria that digest soluble BOD and can be tuned to remove Nitrogen and Ammonia through nitrification and denitrification processes.

Membrane Bioreactor (MBR)

Alternatively, for facilities requiring a very small footprint and high-quality effluent, a Membrane Bioreactor (MBR) is often the preferred biological solution [5]. The Ecologix MBR system replaces traditional secondary clarifiers with submerged, flat sheet Ultra-Filtration (UF) membrane modules submerged directly in the biological tanks. This physical barrier ensures that no suspended solids leave the system, retaining the biomass for maximum efficiency while producing water that is free of solids and low in turbidity.

5. Tertiary Polishing & Filtration

Once the biological stage has removed the bulk of the organic load and nutrients, the water may undergo Tertiary Treatment for final polishing. This stage is crucial for facilities facing strict discharge limits on Phosphorus, heavy metals, or fine particulates [6].

Tertiary Filtration equipment, such as Pressurized Media Filters, are commonly used here. Ecologix manufactures pressure vessels, pressure vessels that can be loaded with various media: sand, Organoclay, multi-media, Activated Glass Filtration Media (AGFM), or Activated Carbon depending on the target contaminant (e.g., carbon for removing trace organics or chlorine).

6. Heavy Metal Removal

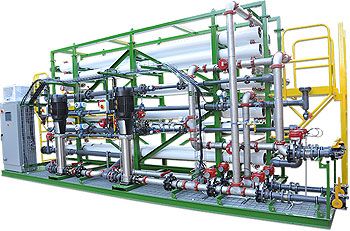

For applications requiring the removal of dissolved heavy metals (like copper, zinc, or chrome) often found in metal plating or mining wastewater, the treatment approach combines chemical precipitation during the Phys/Chem stage with advanced tertiary filtration. After precipitating the metals out of the solution, an Ultrafiltration (UF) or Reverse Osmosis (RO) system from Ecologix can be employed to achieve near-pure water quality, allowing facilities to recycle the water back into their production process.

7. Sludge Handling & Dewatering

A byproduct of all these treatment processes—particularly DAF and biological systems—is sludge. Handling this waste is a critical operational consideration. Liquid sludge is expensive to haul away, so "dewatering" is necessary to reduce its volume. Ecologix addresses this with the Multi Plate Screw Press (MPSP). This automated piece of equipment squeezes water out of the sludge, producing a dry "cake" that is much cheaper to dispose of. It is often preferred over older technologies for its low energy consumption, automation, and self-cleaning capabilities. See more details on these specifications here.

For facilities with specific or heavy-duty dewatering needs, traditional Filter Presses are also available. These use high pressure to force sludge against filter cloths, achieving very high solids content in the final cake. Ecologix offers a range of filter presses suited for heavy industrial sludges, such as those from mining or metal finishing, ensuring that the waste volume is minimized to the greatest extent possible.

8. Turn-Key & Mobile Integration

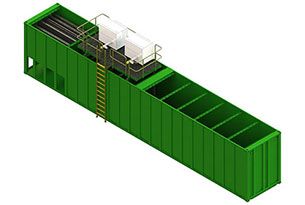

Ultimately, the effectiveness of an industrial wastewater plant relies on the successful integration of these diverse technologies. A food processing plant might require a DAF followed by an MBBR to handle high FOG and BOD, while a metal finisher might need chemical precipitation and a lamella clarifier, followed by specialized filtration. Ecologix Environmental Systems distinguishes itself by not just selling individual components, but by providing complete, turn-key treatment plants designed and built in their own facilities, right here in the U.S.

Their capability extends to mobile and integrated solutions as well, such as the ITS-1500, which combines chemical reaction tanks and DAF technology on a mobile platform for immediate or temporary needs. This flexibility allows them to address unique circumstances, whether it is a remote drilling site or a factory in an urban center with limited space.

9. Conclusion

By leveraging a portfolio that spans from Enhanced DAF technology and Oil Water Separators to advanced MBBR/MBR biological systems and tertiary Filtration, Ecologix ensures that every contaminant (from simple suspended solids to complex nitrogen and phosphorus compounds) is addressed. This holistic approach ensures regulatory compliance, lowers surcharges from municipal sewer systems, and frequently enables water reuse, turning a waste stream into a recoverable asset [1].

10. References

Have a project you would like to discuss?

Contact Ecologix Environmental Systems today to learn more about our engineered solutions.

Contact Us