Summary

Lamella clarifiers, also known as inclined plate clarifiers, utilize a series of inclined plates or tubes to enhance the settling of suspended solids, achieving efficiency in a significantly more compact footprint compared to conventional clarifiers. This article examines their design principles, operational mechanics, technical specifications, applications including biosolids management, challenges, and solutions, supported by equations and comparative data.

Table of Contents

Introduction

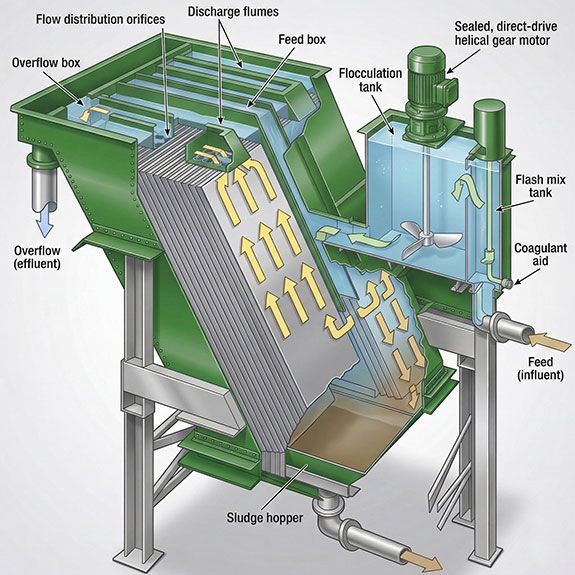

In wastewater treatment, the removal of suspended solids is a critical step to ensure effluent quality. Lamella clarifiers employ inclined plates to increase the effective settling area, allowing accelerated sedimentation of particles. This technology suits facilities handling high volumes of wastewater where space and efficiency matter. The design leverages gravitational forces and optimized flow patterns to separate solids, producing clarified water and concentrated biosolids.

Conventional clarifiers refer to large circular or rectangular settling tanks that rely on gravity sedimentation without inclined plates or tubes, often featuring mechanisms like traveling bridges for sludge removal.

Historical Development and Evolution

The concept of inclined plate sedimentation emerged in the early 20th century, with implementations advancing in the 1970s. Early designs retrofitted existing tanks to boost capacity. Advancements in materials, from concrete to coated carbon steel and polypropylene plates, improved durability. Standards from the American Water Works Association refined these systems, focusing on higher overflow rates and reduced maintenance.

Design Principles

Lamella clarifiers feature parallel plates inclined at 45 to 60 degrees. Plates, spaced 50 to 80 millimeters apart, create multiple settling zones in a tank constructed from carbon steel with epoxy coatings, supported on four legs. Key elements include:

- Plate Configuration: Plates multiply the effective settling surface. For N

plates, each of width W, inclined at angle θ, and length L, the effective settling area is:

Lamella Plates - Ecologix - Inlet and Outlet Structures: Feed enters below the plates to reduce turbulence; clarified water exits via weirs.

- Sludge Hopper: A bottom section collects settled biosolids.

These rely on shallow-depth sedimentation theory, shortening the particle settling path.

Shallow-depth sedimentation theory posits that particle removal efficiency in gravity settlers depends primarily on the available surface area for settling rather than the overall depth of the basin. In lamella clarifiers, the inclined plates divide the tank into numerous shallow layers, each acting as an independent settling zone. This configuration minimizes the vertical distance suspended particles must travel to reach a settling surface, typically reducing it to the plate spacing distance, thereby enhancing sedimentation rates and allowing for higher hydraulic loadings without compromising performance.

Lamella clarifiers are often preceded by or integrated with coagulation and flocculation processes to enhance particle aggregation, though not all designs include these as built-in tanks; standalone units may connect to separate upstream chemical reaction stages for optimal performance in treating fine suspended solids. Coagulation, involving the addition of chemicals like aluminum sulfate or ferric chloride, destabilizes colloidal particles by neutralizing their electrical charges, setting the stage for effective flocculation and subsequent settling in the clarifier.

Operational Mechanics

Wastewater treatment with lamella clarifiers typically begins with pre-treatment steps: coagulation followed by flocculation. In coagulation, coagulants such as aluminum sulfate (alum) or ferric chloride are rapidly mixed into the influent to neutralize particle charges, forming microflocs. Alum is widely used for its cost-effectiveness and ability to form dense flocs in neutral pH ranges, while ferric chloride excels in acidic conditions and for phosphorus removal. Alkalinity plays a critical role, as alum requires sufficient alkalinity to form aluminum hydroxide precipitates; insufficient levels may necessitate pre-dosing with lime or soda ash to maintain optimal pH and avoid operational costs from poor coagulation. Flocculation then gently agitates these microflocs, often aided by flocculants like synthetic polymers (e.g., polyacrylamide) or natural alternatives (e.g., starch-based), to create larger, settleable macroflocs. Polyacrylamide can be anionic (negatively charged for bridging positively charged particles), cationic (positively charged for negatively charged colloids), or non-ionic, with selection tailored to the wastewater's particle zeta potential for effective bridging and macrofloc formation. The pre-treated wastewater enters the clarifier, where flow ascends between plates, with particles settling on surfaces and sliding to the hopper as biosolids. Clarified effluent overflows. Controlled velocities prevent resuspension.

The primary function involves removing total suspended solids (TSS) through sedimentation, where particles with densities greater than water settle out. For fats, oils, and grease (FOG), lamella clarifiers can separate floating materials if designed with skimming mechanisms, though dissolved air flotation units are more specialized for high FOG concentrations.

Particle settling velocity follows Stokes' law for spherical particles in laminar flow:

Where:

- settling velocity (m/s),

- particle density (kg/m3),

- fluid density (kg/m3),

- is gravitational acceleration (9.81 m/s2),

- is particle diameter (m),

- is dynamic viscosity (Pa⋅s).

This assumes Reynolds number < 1. Coagulation and flocculation increase effective d, boosting .

The surface overflow rate (SOR) is:

Where:

- is volumetric flow rate (m3/s),

- is horizontal projected area (m2).

SOR for lamella clarifiers is 10 to 25 m/h, versus 1 to 3 m/h for conventional clarifiers [1].

Types and Variations

Variations include:

- Inclined Plate Clarifiers: Flat plates for general sedimentation

- Tube Settler Clarifiers: Tubular modules for modular installation

- Integrated Systems: With coagulation, flocculation, or chemical dosing for biosolids separation

- High-Rate Variants: Ballasted flocculation for SOR up to 200 m/h [2]

Materials vary, with polypropylene for corrosive settings or stainless steel for strength.

Applications in Wastewater Treatment

Lamella clarifiers serve primary and secondary clarification in municipal and industrial settings. They remove TSS to reduce turbidity and produce biosolids for dewatering or digestion. For FOG, they aid in primary treatment by allowing floatable materials to be skimmed, though efficiency depends on influent characteristics. In biosolids management, they concentrate sludge, reducing volume for thickening or anaerobic digestion. Industries like food processing benefit from handling high solids loads [1].

Table 1: Comparison of Lamella and Conventional Clarifiers in Wastewater Treatment

| Parameter | Lamella Clarifier | Conventional Clarifier (Large Circular/Rectangular Tanks) |

|---|---|---|

| Footprint | Compact (2-10 times smaller) | Large |

| Surface Overflow Rate (m/h) | 10-25 | 1-3 |

| Retention Time (hours) | 1-3 | 2-4 |

| Solids Removal Efficiency (%) | 90-95 | 80-90 |

| Typical Applications | Water, industrial wastewater | Primary sedimentation, biosolids concentration |

Technical Specifications and Calculations

Specifications tailor to influent: plate angle, spacing, tank dimensions. For Q = 100 m³/h at SOR = 15 m/h:

With plates at 55 degrees, actual plate area is per unit.

The critical settling velocity (v_c) represents the minimum velocity required for a particle to be theoretically 100% removed in an ideal Type I (discrete particle) settling scenario, where v_c equals the SOR. Particles with settling velocity v_s ≥ v_c are captured, while those with v_s < v_c may escape. In lamella clarifiers, v_c is closely tied to the hydraulic loading rate (HLR), often referred to as the Hazen velocity, which quantifies the upward flow velocity between plates and must be less than or equal to v_s for effective removal.

The plate configuration equation highlights a key design trade-off: increasing enhances sludge sliding to prevent fouling but reduces , thereby decreasing A_eff and potentially lowering overall capacity. Conversely, a lower θ maximizes A_eff but risks biosolids accumulation if sliding is impeded.

While Stokes' law applies to ideal Type I settling, real wastewater often involves Type II (flocculant) settling, where particles aggregate and v_s increases with depth, or Type III (zone) settling, where high concentrations form a settling blanket with variable density and diameter. In these cases, the Hazen velocity provides a more practical metric for HLR, ensuring design accounts for non-ideal behaviors.

Table 2: Design Parameters for Lamella Clarifiers in Wastewater

| Parameter | Range | Units |

|---|---|---|

| Plate Inclination | 45-60 | Degrees |

| Plate Spacing | 50-80 | mm |

| Surface Overflow Rate | 10-25 | m/h |

| Hydraulic Loading | 0.8-1.5 | m/h (Hazen velocity) |

| Solids Loading Rate | 5-12 | kg/m²/h |

Challenges in Implementation

Plate fouling from biosolids reduces efficiency, so the application of lamella clarifiers must be carefully assessed in those scenarios. High turbidity causes carryover. Compact designs hinder maintenance access. Wastewater variations require dosing adjustments. Hydraulic overloading poses a significant risk; with retention times of 1-3 hours (shorter than 2-4 hours in conventional clarifiers), sudden flow surges can quickly lead to high turbidity carryover in the effluent, as the system has limited buffering capacity.

Sludge rheology complicates management: rapid settling produces highly concentrated biosolids, but if viscosity is too high, sludge may not slide down plates efficiently, causing uneven flow distribution and fouling. This underscores the need for steeper plate angles to promote sliding, though it trades off with reduced effective settling area.

For high concentrations of light, fine particles or FOG, lamella clarifiers may not be optimal; dissolved air flotation (DAF) is often preferred in such cases due to its buoyancy-based separation.

Solutions and Best Practices

Address fouling with removable plates. Pre-treatment with coagulation and flocculation aids settling. Automate controls for flow and dosing to mitigate hydraulic surges and maintain consistent performance. Pilot test for site-specific wastewater; select resistant materials. Integrate sludge systems for biosolids consistency, including rheological assessments to optimize withdrawal rates and prevent buildup.

Conclusion

Lamella clarifiers provide efficient sedimentation in wastewater treatment, suitable for space-limited sites while managing biosolids. Their advantages, supported by proper design, make them essential in many designs.

Glossary

- Alkalinity: The capacity of water or wastewater to neutralize acids, primarily due to the presence of carbonates, bicarbonates, and hydroxides; it influences pH stability and coagulant effectiveness.

- Alum: Common name for aluminum sulfate [Al2(SO4)3], a chemical coagulant used to destabilize particles in wastewater by forming precipitates, often applied for phosphorus removal or in neutral pH conditions.

- Biosolids: Nutrient-rich organic materials from wastewater treatment.

- Coagulation: The chemical process of adding coagulants to destabilize colloidal particles by neutralizing their electrical charges, facilitating aggregation into microflocs.

- DAF (Dissolved Air Flotation): A clarification process using microscopic air bubbles to float and remove suspended solids or oils from wastewater, often preferred for high FOG concentrations as an alternative to sedimentation.

- Effluent: The treated liquid discharged from a wastewater treatment process or unit, such as clarified water from a lamella clarifier.

- Floc: Aggregated clusters of fine particles formed during coagulation and flocculation, which settle more readily than individual suspended solids.

- Flocculation: Aggregating fine particles into larger flocs for settling, following coagulation through gentle mixing.

- FOG: Fats, Oils, and Grease; organic substances in wastewater that can float and be skimmed during clarification.

- Hopper: Funnel-shaped bottom chamber in clarifiers for collecting and dispensing settled solids.

- Influent: The untreated wastewater entering a treatment process or unit, such as raw or pre-treated flow into a lamella clarifier.

- Lamella: Inclined plates or tubes in clarifiers that increase settling surface area.

- Macroflocs: Larger, visible aggregates formed during flocculation by the collision and bridging of microflocs, enhancing settleability in clarifiers.

- m/h: Meters per hour; a unit of velocity used for rates such as surface overflow rate.

- Microflocs: Small initial aggregates of destabilized particles formed during coagulation, serving as precursors to larger macroflocs.

- Overflow Rate (SOR): Flow rate per horizontal area, indicating loading.

- pH: A measure of the acidity or alkalinity of a solution on a logarithmic scale from 0 (highly acidic) to 14 (highly alkaline), with 7 being neutral; it critically affects coagulation efficiency and floc formation.

- Sedimentation: Gravity separation of suspended solids from liquids.

- Shallow-Depth Sedimentation Theory: Principle that settling efficiency relies on surface area rather than basin depth, achieved in lamella clarifiers by inclined plates creating multiple shallow settling zones to minimize particle travel distance.

- SOR: Surface Overflow Rate; the volumetric flow rate divided by the horizontal projected settling area, typically in m/h.

- Stokes' Law: Describes settling velocity of spherical particles.

- TSS: Total Suspended Solids; the dry weight of filterable particles in a water sample, targeted for removal in clarification.

- Weir: Overflow structure in clarifiers that evenly distributes and collects clarified effluent.

FAQ

- What is the primary advantage of lamella clarifiers over conventional ones? They offer a larger effective settling area within a smaller footprint, which allows for higher surface overflow rates and greater treatment capacity per unit area.

- How do inclined plates enhance settling? They shorten the distance particles have to fall before settling out, drawing on the ideas behind shallow-depth sedimentation.

- Can lamella clarifiers handle high solids loads in industrial wastewater? Yes, their design accommodates variable and elevated solids loadings, making them well-suited for demanding industrial environments where consistent performance is needed.

- What maintenance is required? Routine tasks include inspecting and cleaning the inclined plates to avoid buildup and fouling, regularly withdrawing accumulated sludge from the hopper to prevent overflows, monitoring the tank for signs of corrosion or structural wear, and verifying the functionality of any linked chemical dosing or control systems to ensure reliable operation.

- How does the inclination angle impact clarifier performance? A steeper angle, typically 55 to 60 degrees, improves sludge sliding and self-cleaning but can slightly decrease the projected settling area; the ideal angle strikes a balance between efficient particle removal and ease of solids management.

Bibliography

Have a project you would like to discuss?

Contact Ecologix Environmental Systems today to learn more about our engineered solutions.

Contact Us