Summary

Before committing to a major wastewater system overhaul, it's crucial to know if the new technology will actually work. That's where a wastewater treatability study comes in. Think of it as a test drive for your treatment plant. It's a preliminary, small-scale trial that uses your facility's actual wastewater to prove a proposed solution is effective. For pulp, paper, and tissue plants facing challenges with outdated or non-compliant systems, these studies provide a risk-free way to verify performance, ensuring that a significant investment leads to a sustainable and cost-effective solution tailored to your specific needs.

The Power of MBBR Technology 💧

Pulp, paper, and tissue plants produce a uniquely challenging wastewater stream, heavy with lignins, cellulose, and chemicals that can overwhelm conventional activated sludge (CAS) systems. A much more efficient and resilient solution is the Moving Bed Biofilm Reactor (MBBR). Unlike older systems that rely on free-floating biomass, an MBBR uses thousands of small plastic carriers that provide a massive surface area for a robust, concentrated biofilm to grow. This innovation can double or even triple the treatment capacity of an existing tank, making it a perfect fit for mills where space is limited and wastewater loads fluctuate. The self-regulating biofilm is incredibly resilient, ensuring consistent compliance with discharge permits.

The Ecologix Advantage ✨

While MBBR is a powerful technology, Ecologix Environmental Systems enhances its performance even further. The unique design of Ecologix's Eco-Chip MBBR media maximizes the surface area for biofilm growth, boosting treatment efficiency.

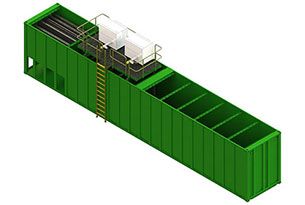

More importantly, Ecologix specializes in retrofitting failing or inefficient systems. By converting an old basin into an MBBR or an Integrated Fixed-Film Activated Sludge (IFAS) system, plants can get a state-of-the-art upgrade using their existing tanks. This approach dramatically cuts down on capital costs and installation downtime compared to building a new system from the ground up.

Case Study: A Turnaround in Oklahoma

A large paper mill in Oklahoma offers a clear example of this technology's impact. The facility struggled for years with a failing biological system that was overloaded, couldn't meet discharge standards, and caused odor complaints from the community. After Ecologix retrofitted the plant to an MBBR, the facility not only solved its compliance and odor issues but also improved operational efficiency and lowered costs. The project included a fully automated sludge dewatering system and an upgraded control system, modernizing the entire wastewater operation.

Partner with the Experts at Ecologix 🤝

For pulp, paper, and tissue plants, embracing advanced wastewater treatment isn't just about meeting regulations, it's about building a more profitable and sustainable future. Ecologix Environmental Systems is your one-stop partner for modernizing your operations.