Automotive manufacturing is a high-tech, precision-driven industry. But behind the gleaming assembly lines lies a significant environmental challenge: complex wastewater. From metal plating and parts washing to painting and finishing, each step generates effluent loaded with a diverse range of tough-to-treat contaminants. To meet strict environmental standards and uphold corporate sustainability goals, the industry is turning to advanced solutions like the Moving Bed Biofilm Reactor (MBBR).

The Complex Cocktail of Automotive Wastewater

Wastewater from an automotive plant is a mix of inorganic and organic pollutants that can be toxic and environmentally harmful. Key characteristics include:

- Heavy Metals: Processes like electroplating and phosphating introduce metals such as chromium, zinc, nickel, and copper into the wastewater.

- Oils & Grease: Machining, stamping, and parts washing result in high concentrations of emulsified oils and greases.

- Solvents & VOCs: Painting and coating operations release volatile organic compounds (VOCs) and other chemical solvents.

- High Total Suspended Solids (TSS): From metal fines, paint sludge, and other particulate matter.

The variable nature of these contaminants, combined with fluctuating production schedules, makes treating this wastewater a significant operational challenge.

The Critical Link: Phys/Chem Pretreatment

While the MBBR is a powerhouse for biological degradation, it cannot function in a vacuum. Automotive effluent contains high concentrations of emulsified oils, heavy metals, and suspended solids that are inhibitory (and often toxic) to biological cultures. To protect the MBBR and ensure system stability, a robust Physical/Chemical (Phys/Chem) Pretreatment stage is mandatory.

This process typically follows a three-step sequence to "condition" the water for biological treatment:

- Chemical Coagulation and pH Adjustment

The process begins in Chemical Reaction Tanks (or inline Floc Tubes for space-saving efficiency). Here, the pH is adjusted to the "sweet spot" for metal precipitation. Coagulants are injected to neutralize the electrical charges of microscopic particles and emulsified oils, causing them to begin clumping together.

- Flocculation

Once the particles are destabilized, polymer (flocculant) is added. In the controlled energy environment of a reaction tank or the serpentine path of a floc tube, these small particles collide and bind into larger, heavier "flocs." This step transforms a cloudy, emulsified liquid into a mixture of clear water and distinct solid masses.

- Primary Clarification: DAF vs. Lamella

The final step of pretreatment is the physical separation of these flocs from the water stream. Depending on the specific contaminants, one of two technologies is employed:

- Dissolved Air Flotation (DAF): Ideal for automotive waste high in oils, grease, and light solids. Micro-bubbles attach to the flocs, lifting them to the surface where they are skimmed off as sludge.

- Lamella (Incline Plate) Clarifiers: Best suited for heavy, metal-rich solids that settle quickly. These units use a series of inclined plates to provide a massive settling area within a very small footprint.

The Result: By the time the wastewater exits the Phys/Chem stage, the "heavy lifting" of solids, heavy metals, and oil removal is complete. The MBBR is then free to focus exclusively on the dissolved organic compounds (BOD/COD) it was designed to treat, ensuring a long life for the biofilm and consistent discharge compliance.

MBBR: The High-Performance Engine for Treatment

An MBBR system is uniquely suited to handle the harsh conditions of automotive wastewater. The core of the technology is the biofilm that grows on thousands of engineered plastic carriers suspended within the reactor. This creates an incredibly dense and resilient population of microorganisms capable of breaking down a wide array of pollutants.

The self-regulating biofilm can withstand the toxic effects of heavy metals and chemical shocks, providing a level of stability that conventional treatment systems struggle to achieve. It creates a robust biological ecosystem that adapts to the specific contaminants in the waste stream.

Key Advantages for the Automotive Sector

Extreme Resilience

The attached-growth biofilm is highly resistant to the toxic shock loads from heavy metals and chemical dumps, ensuring consistent and reliable treatment without system failure.

Superior Pollutant Removal

MBBR is highly effective at reducing BOD and COD, and it facilitates the removal of specific contaminants like oils, phenols, and some heavy metals through biological action and biosorption.

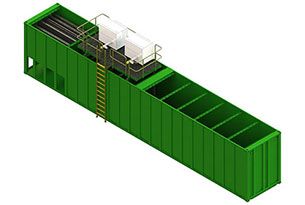

Compact & Scalable

The high-efficiency treatment occurs in a small footprint, saving valuable space in a manufacturing facility. The system can be easily scaled to match plant production increases.

Operational Simplicity

MBBR systems are self-regulating and require minimal operator intervention, reducing labor costs and simplifying compliance management.

The Road to a Greener Assembly Line

For automotive manufacturers, effective wastewater treatment is not just a regulatory requirement—it's a critical component of a sustainable brand identity. MBBR technology provides a powerful, reliable, and cost-effective solution to manage complex industrial effluent.

By adopting MBBR, automotive plants can ensure they are not only producing high-quality vehicles but also protecting the environment with high-quality water discharge.