The dairy industry, responsible for producing essentials like milk, cheese, and yogurt, faces a significant environmental challenge: its wastewater. Rich in organic matter, fats, and nutrients, dairy effluent requires robust and efficient treatment to meet stringent discharge regulations. Enter Moving Bed Biofilm Reactor (MBBR) technology—a game-changing solution perfectly suited for the demands of dairy processing.

The High Stakes of Dairy Wastewater

Wastewater from dairy plants is notoriously difficult to treat. It's characterized by:

- High Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD): Due to milk solids, sugars (lactose), and proteins.

- Elevated Fats, Oils, and Grease (FOG): Which can clog systems and hinder biological treatment.

- Fluctuating Loads: Production schedules, cleaning cycles (Clean-In-Place systems), and product changeovers create highly variable wastewater flow and composition.

- Nutrient Content: High levels of nitrogen and phosphorus that must be removed before discharge.

Traditional treatment systems often struggle with these fluctuations and require a large physical footprint, which can be a major constraint for existing facilities.

What is & Why MBBR Technology?

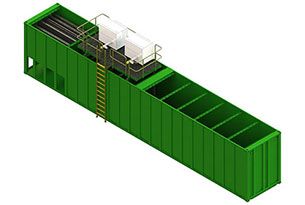

A Moving Bed Biofilm Reactor is an advanced biological treatment process that utilizes thousands of small, free-floating plastic carriers (media) within an aeration tank. These carriers, designed with a high surface area, provide a protected environment for a dense population of microorganisms (a biofilm) to grow. This biofilm is the workhorse of the system. As wastewater passes through the tank, the microorganisms consume the organic pollutants, converting them into harmless byproducts like water and carbon dioxide. Continuous aeration keeps the media and the biofilm suspended and mixed, ensuring optimal contact between the microorganisms and the contaminants.

Key Benefits of MBBR for the Dairy Industry

Compact Footprint

The immense surface area provided by the biofilm carriers means MBBR systems can treat high loads of wastewater in a much smaller tank compared to conventional activated sludge systems, saving valuable plant space.

Exceptional Resilience

The attached-growth biofilm is highly resilient to shock loads and variations in pH and temperature—common occurrences in dairy processing. This stability ensures consistent, reliable treatment performance.

High Efficiency

MBBRs achieve very high removal rates for BOD, COD, and ammonia. The specialized microbial communities can be tailored for specific treatment goals, including nitrification and denitrification.

Simple Operation

With no need for sludge recirculation (a key part of activated sludge systems), MBBRs are simpler to operate and maintain, reducing labor costs and operational complexity.

A Sustainable Future for Dairy Processing

For dairy facilities looking to upgrade their wastewater treatment capabilities, comply with environmental regulations, and optimize operational costs, MBBR technology presents a compelling solution. Its ability to efficiently handle the high-strength, variable wastewater streams from milk, cheese, and yogurt production makes it a superior choice for a forward-thinking industry. By investing in MBBR, dairy processors can not only ensure environmental compliance but also enhance their operational sustainability, turning a challenging byproduct into a manageable and efficiently treated resource.