Wastewater from coking and steel manufacturing is one of the most challenging industrial streams to treat. It contains a highly toxic and complex mixture of contaminants that can destroy conventional biological treatment systems. Ecologix Systems' MBBR provides a robust, reliable solution engineered to perform in this harsh environment.

The Challenge: A Toxic Chemical Cocktail

Effluent from coke quenching, gas scrubbing, and finishing processes is laden with compounds that are acutely toxic to microorganisms:

- High-Concentration Ammonia: Leads to severe environmental damage and requires efficient nitrification for removal.

- Cyanides & Thiocyanates: Highly toxic compounds that require specialized bacteria to break down.

- Phenols and Polynuclear Aromatic Hydrocarbons (PAHs): Carcinogenic and difficult to degrade organic compounds.

- Variable Loads: Batch processes and production changes create shock loads that cause system failure in traditional plants.

The Solution: The Ecologix MBBR Advantage

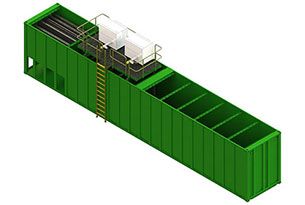

The Ecologix Moving Bed Biofilm Reactor is uniquely suited to treat coke and steel wastewater. Unlike suspended growth systems, our technology relies on a massive population of bacteria growing in a protected, fixed-film biofilm on our proprietary biocarriers.

This design creates an incredibly resilient ecosystem. The outer layers of the biofilm absorb toxic shocks, protecting the specialized microbes within. This allows for the stable cultivation of different bacteria in different zones, enabling a multi-stage process in a compact system to simultaneously remove ammonia, phenols, and cyanides.

Key Advantages for Steel & Coke Producers

Guaranteed Regulatory Compliance

The system's stability and high efficiency ensure consistent removal of toxic compounds, meeting the most stringent environmental discharge standards.

Extreme Resilience to Toxicity

Our fixed-film process withstands the chemical shocks and variable loads that cause other biological systems to fail, ensuring continuous operation.

Reduced Footprint & Simplicity

The MBBR's high-rate treatment process requires significantly less space than conventional systems and is highly automated, reducing operational complexity.

Cost-Effective & Reliable

Avoids the high costs of non-compliance fines, reduces chemical usage compared to purely physical/chemical treatment, and provides long-term operational reliability.

Achieve Total Compliance for Your Most Difficult Wastewater

Get in touch with our experts today

Get a Free Quote