Flocculation tubes are essential in modern wastewater treatment, playing a critical role in transforming contaminated water into clear, reusable effluent. These innovative components facilitate the aggregation of suspended particles into larger, easily settleable "flocs," paving the way for efficient contaminant removal.

As a leading design and manufacturing expert in wastewater treatment solutions, Ecologix Environmental Systems has developed an advanced line of flocculation tube systems that stand as prime examples of cutting-edge flocculation technology.

Precision Manufacturing

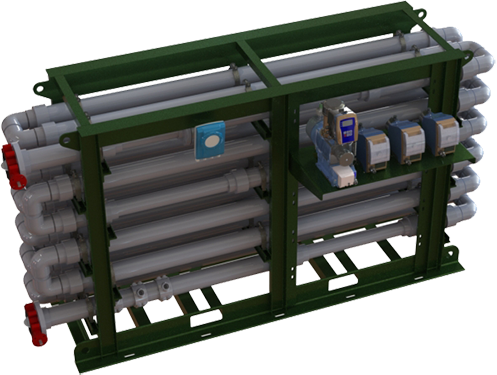

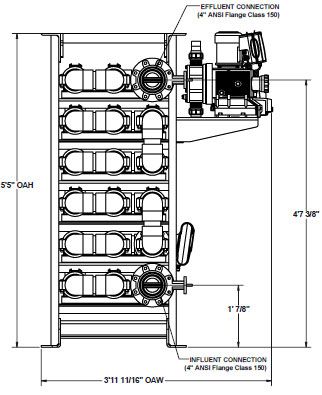

Ecologix flocculation tubes are built for durability and performance. We construct them from PVC (Polyvinyl Chloride), chosen for its exceptional resistance to chemical corrosion and long lifespan. Depending on the specific model and application, we use either Schedule 80 or Schedule 40 piping. Any non-wetted metal components are typically painted ASTM A36 carbon steel, ensuring robust support.

Our manufacturing process involves precision engineering to create a highly efficient plug-flow reactor configuration. These tubes integrate strategically placed injection ports for introducing vital treatment chemicals like coagulants, pH adjusters, and polymers. Each tube is fabricated to exact dimensions, guaranteeing consistent flow dynamics and seamless integration with other wastewater treatment components, such as Ecologix's renowned Dissolved Air Flotation (DAF) systems, via flanged connectors.

A key innovation is the triple-pass design of Ecologix's flocculation tube system. This extends contact and reaction time by up to 30% compared to traditional double-pass systems, significantly boosting flocculation efficiency. For real-time monitoring and simplified maintenance, we also integrate sampling drain valves and sensor ports directly into the design.

The Design Rationale

The core philosophy behind Ecologix flocculation tube design is to achieve maximum coagulation and flocculation within a minimal footprint. The plug-flow reactor configuration is engineered to generate controlled turbulence, which promotes the thorough and effective mixing of chemicals with wastewater.

This turbulence ensures that coagulants (like ferric chloride or PAC) effectively neutralize particle charges in the initial stage. Subsequently, polymers are introduced to facilitate rapid floc growth. The innovative triple-pass design maximizes residence time, allowing ample opportunity for superior particle aggregation.

We strategically place injection ports to facilitate sequential chemical dosing—coagulant first, followed by pH adjustment, and then polymer—to optimize the entire flocculation process. The compact design significantly reduces space requirements compared to outdated, traditional reaction tanks.

Smart Integration: Instrumentation & Precise Chemical Dosing

To ensure unparalleled control and efficiency, Ecologix flocculation tubes come equipped with advanced instrumentation and dosing systems, conveniently mounted on a sturdy steel frame shelf for easy accessibility and maintenance.

- Flow Meter: An integrated flow meter continuously monitors wastewater flow rates, ensuring consistent hydraulic loading and precise chemical dosing ratios. Accurate flow measurement is paramount to prevent under- or overdosing, which can compromise flocculation efficiency or lead to increased operational costs.

- pH Meter: A dedicated pH meter actively monitors and adjusts the wastewater's pH. Maintaining an optimal pH range (typically 6-8) is crucial, as pH significantly impacts the performance of coagulants and flocculants (e.g., enhancing the effectiveness of ferric chloride or polymer-based flocculation).

- Polymer Emulsion System: This system ensures the precise delivery of liquid polymer, vital for forming strong, settleable flocs. It automates polymer activation and dilution, guaranteeing consistent flocculant quality and minimizing waste.

- Chemical Dosing Pumps: Mounted securely on the steel frame shelf, these pumps precisely deliver necessary chemicals. Typically, this includes pumps for acid (e.g., sulfuric acid) to lower pH, caustic soda (sodium hydroxide) to raise pH, and dedicated polymer dosing. These pumps provide accurate, automated dosing, which is critical for maintaining process stability and meeting stringent discharge requirements. Ecologix selects pumps known for their reliability, digital control capabilities, and compatibility with corrosive chemicals, ensuring long-term, dependable performance in demanding wastewater treatment plants.

Optimized Sizing for Peak Performance

Ecologix offers a standard line of flocculation tubes designed to accommodate a wide range of flow rates, from the compact FLT-215 (20 - 50 GPM / 4.5 - 11.4 m³/hr.) to the high-capacity FLT-1210 (900 - 2,000 GPM / 204.4 - 454.2 m³/hr.).

Proper sizing is crucial and involves meticulously matching the wastewater flow rate to the tube's design capacity. This ensures optimal coagulation and flocculation while preventing common operational issues. The Ecologix Floc Tube System's triple-pass design extends contact and reaction time, with retention times carefully calculated based on a minimum velocity of 2 ft/second to prevent solids from settling. If the flow rate is too low for the pipe size, solids can accumulate, leading to clogging and reduced treatment efficiency.

Conversely, excessively high flow rates can cause turbulence that shears floc particles, severely reducing flocculation effectiveness and allowing contaminants like Total Suspended Solids (TSS) and Fats, Oils, and Grease (FOG) to pass through untreated. The required retention times also depend on the specific chemicals used—coagulants like alum or ferric sulfate typically need shorter detention times, while polymers for flocculation require more time to form stable macro-flocs.

Diverse Business Applications

Flocculation tubes are indispensable across virtually every industry with onsite wastewater treatment plants. Ecologix's advanced systems are found in a wide range of sectors, including:

- Oil and Gas: Removing emulsified oils and suspended solids from frac water and produced water.

- Food and Beverage: Effectively treating high levels of fats, oils, and grease (FOG).

- Automotive and Manufacturing: Essential for treating metals-laden wastewater, ensuring strict compliance with environmental regulations.

- Municipal Wastewater Treatment: Enhancing solids removal before discharge or further treatment.

Historical Context

The concept of flocculation in wastewater treatment dates back to the early 20th century, when chemical coagulation emerged as a method to improve sedimentation. Early systems relied on cumbersome, space-intensive reaction tanks that demanded significant maintenance.

The late 20th century saw a significant advancement with the development of pipe flocculators, offering compact, highly efficient alternatives. Ecologix, founded over 20 years ago, has been at the forefront of refining this technology, introducing pivotal innovations like the triple-pass design and seamless integration with DAF systems.

The modern incorporation of advanced instrumentation, such as real-time meters and sophisticated polymer systems, reflects the industry's ongoing shift toward automation and precision in the 21st century. This evolution is driven by ever-stricter environmental regulations and the continuous demand for more cost-effective and sustainable solutions.

Conclusion: Ecologix - Your Partner in Advanced Wastewater Treatment

Ecologix Environmental Systems' flocculation tubes embody modern wastewater treatment technology at its best. They combine robust manufacturing, thoughtful design, and advanced instrumentation to deliver exceptionally efficient solids removal.

About Ecologix Environmental Systems

Ecologix Environmental Systems LLC is the design, bid, and build leader for wastewater treatment plants. From the Sea of Japan to the oil fields of Texas, we solve the world's most complicated challenges in water and wastewater designs, delivering innovative and reliable solutions.

Ready to discuss your wastewater treatment needs?

Contact Us Today! Explore Our Solutions