Wastewater Treatment Solutions for Industry

Ecologix provides comprehensive wastewater treatment technologies and services for all areas of industry including automotive, bakeries, food and beverage, slaughterhouses, mining, municipal, produced water, and more. We engineer and manufacture a wide variety of wastewater treatment systems including Dissolved Air Flotation (DAF), Packaged Sewage Treatment, MBBR Systems, Oil Water Separators, Frac Water Recycling, Bag Filters, Chemicals for Wastewater Treatment and essentially all the required equipment for any industrial or commercial wastewater treatment need.

A Selection of Our Products and Services

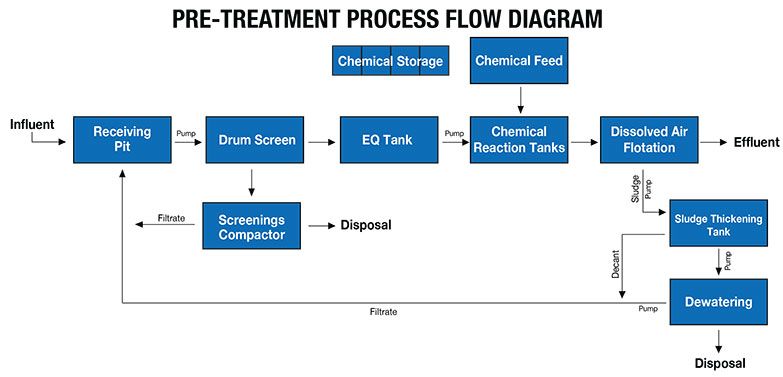

Our expertize in the wastewater industry extends from pre treatment to post treatment and everything in between. Explore some of many offerings below.

Above Ground Oil Water Separators

Ecologix oil water separators remove free and mechanically emulsified oils at rates between 2 and 70 gallons per minute. They are available in above and below ground configurations.

Chemicals For Wastewater Treatment

Ecologix offers a broad range of specialty chemical products for wastewater treatment across a wide range of applications and industries.

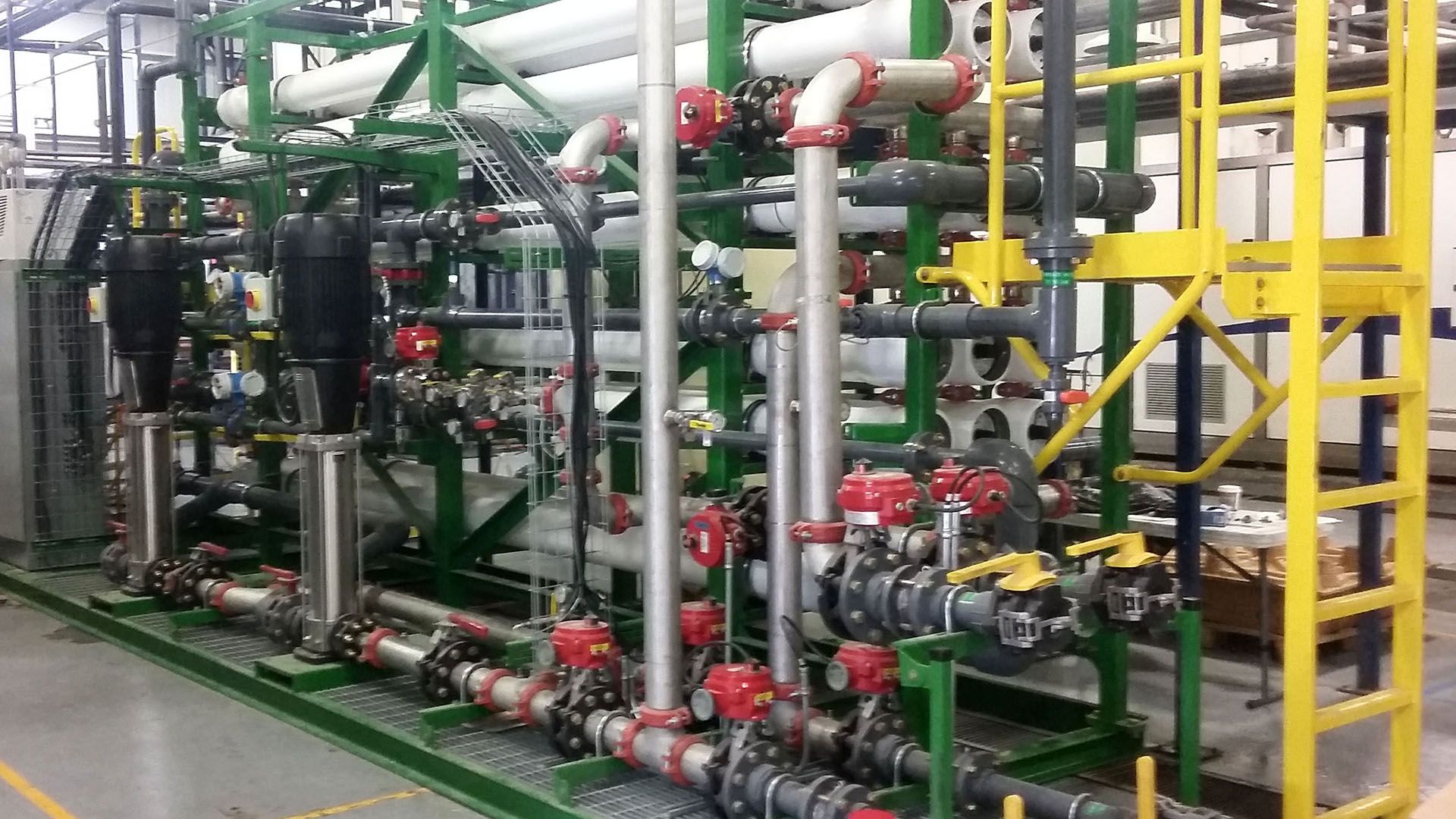

High Rate Auto Backwash Pressure Filters

High Rate Automatic Backwashing Sand Media Filters are designed for general-purpose water filtration. These permanent media automatic backwashing filters will remove organic and/or inorganic suspended solids down to 20 microns in size.

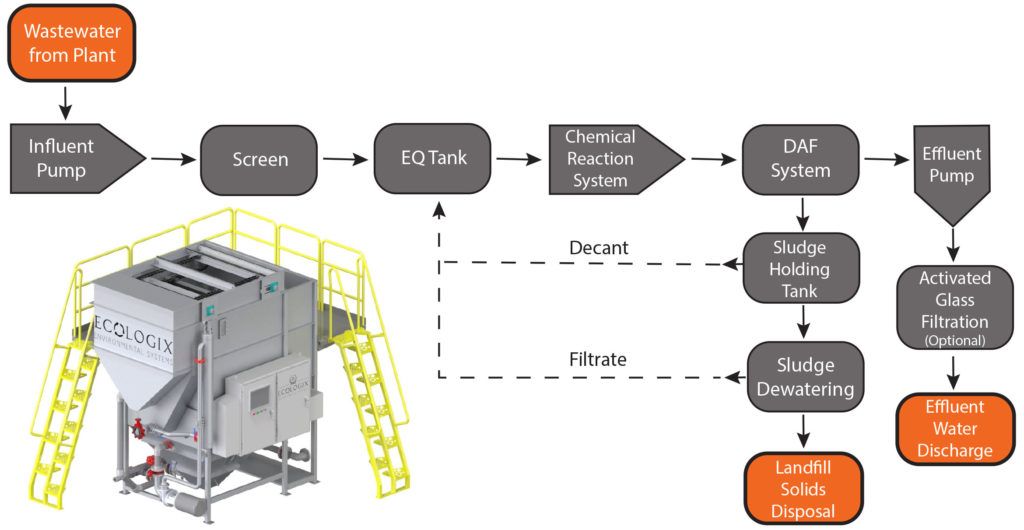

Dissolved Air Flotation (DAF)

The Ecologix Enhanced DAF is a complete primary (phys/chem) treatment system. Incredibly versatile and efficient chemical precipitation and physical separation system for industrial wastewater primary treatment.

Activated Carbon

Activated carbon is very effective in air and water purification applications, as well as precious metal recovery or removal.

Bag & Cartridge Filter Vessels

Ecologix offers a complete selection of both Bag and Cartridge Filter Vessels that are designed for a variety of filtration applications..

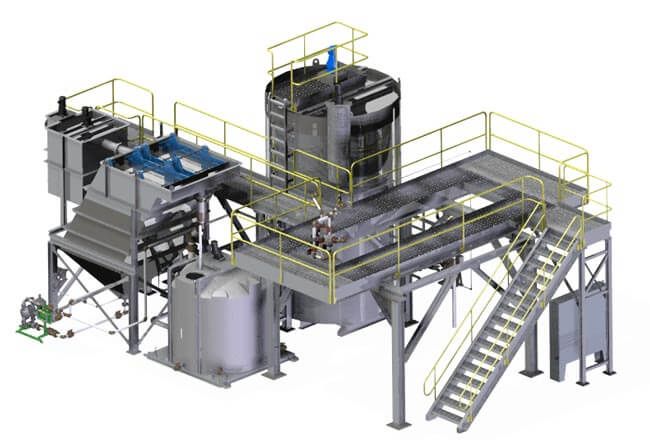

Multi Plate and Filter Presses

Disposing of this sludge can often prove very expensive and for that reason, a sludge dewatering system is a great option for reducing costs. Ecologix provides affordable multi plate screw presses as well as filter presses.

A Selection of The Industries We Serve

With over 20 years of experience serving the wastewater treatment needs of commercial and industrial clients we are confident we can solve your industrial wastewater treatment needs. Below is a selection of the industries we serve, click here to see more.

Automotive Industry

Ecologix provides comprehensive wastewater treatment technologies and services for the automotive industry, including E-Coat paint processes.

Dairy

Producing milk, butter, cheese, or yoghurt, using pasteurization or homogenization produces wastewater with high levels of BOD and COD loads and must be reduced before being discharged to municipal treatment facilities.

Food & Beverage

Ecologix Environmental Systems offers a comprehensive selection of wastewater equipment and technologies that solve the challenges that fats, proteins, and carbohydrates pose to the food and beverage industry.

Ice Cream

Having a problem with excessive FOG (fats, oils and grease) in your effluent wastewater? Ecologix Environmental Systems offers a comprehensive selection of wastewater equipment and technologies that can save your money on your process.

Meat and Poultry

In the meat processing industry, water is used extensively for washing the cattle, sheep, or pig carcasses. Water is also used for sanitizing and thoroughly cleaning all equipment used in the process at the facility.

Mining & Metals Removal

Ecologix provides a complete range of integrated water and wastewater treatment systems and services to clean metals-laden wastewater from mining operations.

Municipal Wastewater Treatment

Ecologix understands that your municipality's needs are unique and of the highest priority. We offer a large array of custom technologies and services for water and sewage treatment to ensure flexible, cost-effective treatment solutions specific to your project needs.

Produced Water / Fracking Wastewater Treatment

Ecologix has the solution for recycling produced water. We pioneered mobile DAF treatment technology for produced water recycling and reuse. For more than a decade, Ecologix has developed turn-key solutions for water reuse for oil and gas fracking operations.

Wastewater Industry Articles

IFAS and MBBR Systems revolutionize efficiency

Pulp, paper, and tissue plants face mounting pressure to comply with stringent environmental regulations, manage high-strength wastewater, and maintain cost-effective operations with aging treatment systems. Many facilities rely on outdated biological processes like conventional activated sludge (CAS), which struggle to handle the unique demands of industrial effluents. Upgrading to Moving Bed Biofilm Reactor (MBBR) or Integrated Fixed-Film Activated Sludge (IFAS) systems offers compelling advantages in performance, cost, and sustainability tailored to these industries.

Oklahoma Paper Mill Wastewater Treatment Plant Upgrade

The transformation of an old SBR system to an advanced Moving Biofilm Bed Reactor (MBBR) improves operational efficiency, reduces costs and eliminates odors, ensuring environmental compliance and restoring community confidence.