Slaughterhouse & Rendering Plant Wastewater Treatment

INDUSTRY TYPE – Food Processing – Slaughterhouse & Rendering Plant

Ecologix Environmental Systems offers a comprehensive selection of wastewater equipment and technologies that solve the challenges that fats, oils, grease, proteins, and carbohydrates pose to slaughterhouses and rendering plants. Whether your process requires pretreatment, biological treatment, membrane filtration, disinfection, or odor removal, Ecologix has the expertise and treatment technologies to meet and exceed your compliance standards.BACKGROUND / HAZARDS PRESENTED BY SLAUGHTERHOUSE WASTEWATER

In commercial-level slaughterhouse and rendering plant applications, water is used as an ingredient, an initial and intermediate cleaning source, and/or the principal agent for sanitizing plant equipment and work areas. As a result of this extensive water use, the slaughterhouse and rendering plant industry’s primary concern is that water and wastewater is handled in the most cost-effective method and reused in whatever capacity possible to reduce costs and remain environmentally compliant.For optimal effectiveness and efficiency, process design for each slaughterhouse and rendering plant application should be specific to your plant needs. When the main concern is to reduce regulated constituents to permissible discharge levels, a pretreatment system is often the most direct and cost-effective solution. You can achieve significant removal of suspended solids, oil and grease, and BOD by implementing a system based on the Enhanced Dissolved Air Flotation process.

INFLUENT CHARACTERISTICS

These figures represent typical measured content levels of major contaminants in wastewater as it issues from the slaughterhouse or rendering plant:

- COD (Chemical Oxygen Demand) – 4,500-12,000

- BOD (Biological Oxygen Demand) – 2,500-8,000

- TSS (Total Suspended Solids) – 600-4,500

- FOG (Fats, Oil & Grease) – 100-2,000

EFFLUENT – REQUIRED CHARACTERISTICS

These figures represent typical required content level limits of major contaminants in treated wastewater before it is allowed to be discharged into public water supplies:

- COD (Chemical Oxygen Demand) – 500 – 1,000 mg/L

- BOD (Biological Oxygen Demand) – 250 – 500 mg/L

- TSS (Total Suspended Solids) – 250 mg/L

- FOG (Fats, Oil & Grease) – 100 mg/L

OPTIMUM TREATMENT SOLUTIONS

Pretreatment of wastewater from a slaughterhouse or rendering plant is necessary before discharging to a municipal sewer system, because municipal treatment plants are incapable of removing the contaminant densities typical of these plants’ wastewater. A very efficient and cost-effective way to accomplish effective pretreatment is through the operation of a Dissolved Air Flotation (DAF) system. These systems are the optimal solution for removal of materials such as suspended solids, fats, oil, and grease (FOG).

Pretreatment using an enhanced DAF system in a commercial food or beverage processing plant will allow for reduction of FOG by up to 99% and Total Suspended Solids (TSS) by up to 97%. The requirement for flocculants, as well as pH adjustment of the water, for effective FOG removal can be fully automated, using the Ecologix Enhanced Dissolved Air Flotation System.

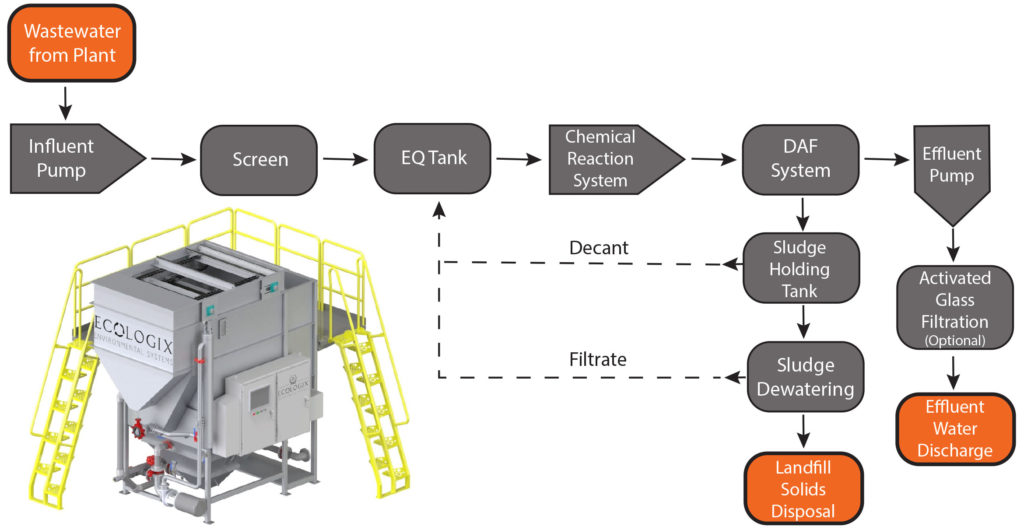

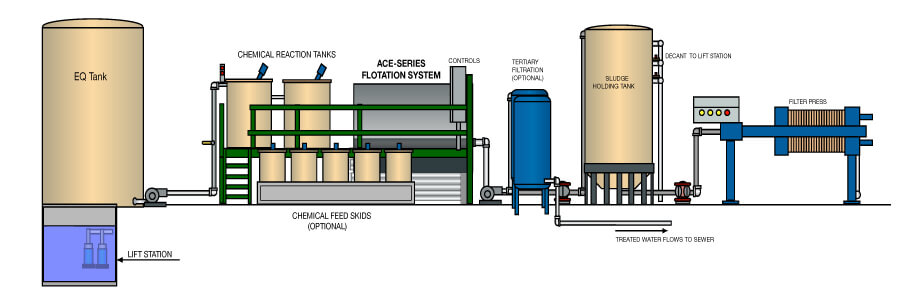

PROCESS DESCRIPTION

- A DAF system utilizes a separation technique that injects microscopic air bubbles into the DAF tank.

- These tiny bubbles attach to the insoluble pollutant materials, floating them to the surface the way a life preserver keeps a person afloat.

- Certain materials used in food processing are heavier than water. They require the addition of flocculants—which attract suspended contaminant particles—and air. When combined, these two substances cause the pollutants to join in clusters and force them to float to the pretreatment vessel’s surface.

- These accumulating contaminants at the surface of the DAF vessel are what is known as “sludge.” They are then scraped off the surface of the water and removed from the treatment process.

- Clean water then exits at the bottom of the DAF vessel and can now be safely discharged to the sewer.

CASE IN POINT

Problem

Lime Springs Beef, located in Lime Springs, Iowa, built a new slaughterhouse facility that processes up to 44,000 GPD (or 30 GPM). It was generating high levels of Suspended Solids (TSS).

The slaughterhouse could not discharge its wastewater to the municipal sewage treatment plant, due to very high levels of biological oxygen demand (BOD). Discharging the untreated slaughterhouse wastewater would send high BOD loads to the municipal wastewater treatment plant and cause a variety of problems.

Requirement

The slaughterhouse would need to meet stringent pretreatment regulations in order to be permitted to discharge its wastewater to the public collection system to be treated at the local wastewater treatment plant.

Solution

Our Ecologix E-505 DAF system was installed at the location. The DAF system includes the following components:

- Polymer Activation System

- Chemical Feed System

- Rotary Drum Screen

- Sludge Pump Skid

- Sludge Dewatering Bin

- PLC Control System to operate all the related pretreatment equipment

The Final Results

The DAF system is now properly treating the slaughterhouse’s wastewater, to lower the TSS, FOG and BOD loads to acceptable levels for entering the public wastewater treatment plant.

If your commercial slaughterhouse or rendering plant is struggling to meet strict new wastewater discharge requirements, call 678-514-2100 or contact us today. We will take care of setting you up with a custom, onsite package plant. You may be surprised how affordable a fully engineered, custom solution may be! We have specialized expertise in all food-related industries.