- Automotive

- Bakeries

- Biodiesel

- Breweries

- Candy Manufacturing

- Dairy

- DAF Wastewater Treatment Industries

- Food & Beverage

- Ice Cream

- Iron Removal

- Latex Removal

- Meat & Poultry

- Mining & Metals

- MBBR Wastewater Treatment Industries

- Municipal

- Oil Water Separator Industries

- Paper and Pulp

- Power Plant

- Produced Water for Oil & Gas

- Produced Water Salt Water Disposal

- Slaughterhouse / Abbatoir

Meat and Poultry Wastewater Treatment

Ecologix provides comprehensive wastewater treatment technologies and services for every facet of the meat and poultry processing industries. From preliminary screening of grit or feathers to physical/chemical separation and sludge management, we will help bring your facility into compliance with local wastewater discharge permit requirements.

Federal regulations dictate that a complete cleaning and sanitation process be conducted after every killing and processing shift at the plant. This cleanup period generally uses considerably more water than the actual processing of the meat. As a result of there often being time between shifts and the processing cleanup phases, the generation of wastewater can be inconsistent.

To discuss your meat or poultry processing wastewater treatment application, call on one of our professional Engineers to request a budgetary proposal for your specific requirements.

Background / Hazards Presented By Food & Beverage Producer Wastewater

All types of meat processes generate wastewater with similar characteristics. They each contain high levels of TSS, FOG, and BOD, making them hard on a municipal treatment plant that may become overwhelmed when it also has many other customer flows to handle. The inconsistent nature of meat and poultry processing plant flows only exacerbates this difficulty, because the downstream municipal plant cannot easily anticipate and plan for high-load flows.

In these types of facilities, cities do the only thing they can to compensate for this difficulty: They collect monetary surcharges from high-load customers, based on discharge loadings. These surcharges can reach tens of thousands of dollars per month, taking a significant bite out of profitability.

When such a situation gets to the point where the municipal wastewater treatment facilities are regularly overwhelmed, unable to handle flows from high-load industries, cities may decide to terminate discharge permits. This forces businesses to either figure out a solution or shut down their plants entirely. This not only creates a bad situation for the business, but can disrupt entire economies in smaller (especially rural) areas.

Do not wait for such a scenario to creep up on your operation. Instead, choose to install our Enhanced Dissolved Air Flotation (DAF) system, the best pretreatment option for such cases. By applying this type of physical/chemical separation process, facilities can completely remove TSS, FOG and high concentrations of BOD. When properly designed, such a pretreatment system will help bring effluents down to permissible levels for sustainable discharge to the city sewer.

Typical Content Levels Of Industry Wastewater Before Treatment

| Parameter | Raw Water | Pre-Treatment Reduction |

|---|---|---|

| Total Suspended Solids (TSS) | 600 - 4,500 mg/L | up to 99% |

| Fat, Oil, & Grease (FOG) | 100 - 2,000 mg/L | up to 99% |

| Biochemical Oxygen Demand (BOD) | 2,500 - 8,000 mg/L | up to 85% |

| Chemical Oxygen Demand (COD) | 4,500 - 12,000 mg/L | up to 75% |

Influent Characteristics

These figures represent typical measured content levels of major contaminants in wastewater as it issues from the meat and poultry production plant:

- COD (Chemical Oxygen Demand) - 4,500-12,000

- BOD (Biological Oxygen Demand) - 2,500-8,000

- TSS (Total Suspended Solids) - 600-4,500

- FOG (Fats, Oil & Grease) - 100-2,000

Effluent - Required Characteristics

These figures represent typical required content level limits of major contaminants in treated wastewater before it is allowed to be discharged to publicly owned treatment works (POTWs):

- COD (Chemical Oxygen Demand) - 500-1,000

- BOD (Biological Oxygen Demand) - 250-500

- TSS (Total Suspended Solids) - 250

- FOG (Fats, Oil & Grease) - 100

Optimum Treatment Solutions

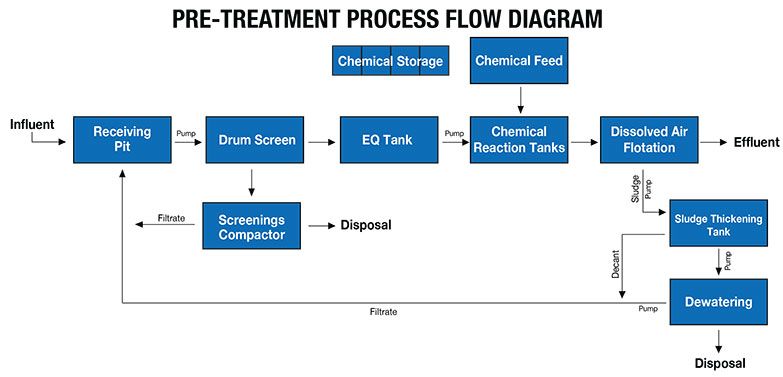

Pretreatment of wastewater from a meat and poultry processing plant is necessary before discharging to a municipal sewer system because municipal treatment plants are incapable of removing the contaminant densities typical of these plant's wastewater. A pretreatment program is needed and, in this case, focuses on reducing contaminants that result in surcharges. For meat processors, that means removing TSS, FOG, and BOD. The video below shows a pretreatment facility centered on Dissolved Air Flotation (DAF) technology.

Pre-treatment systems are sized by daily flow and hours of operation. A facility that produces 60,000 gallons per day of wastewater could process it at approximately 42gpm, 24 hours a day. Sometimes it makes economic sense to process daily wastewater in half the time - 80 GPM for a 60,000 GPD flow. Finding the balance between capital and operational expenses is the key to sustainable success.

Pretreatment using an enhanced DAF system in a commercial meat processing plant will allow for reduction of FOG by up to 99% and Total Suspended Solids (TSS) by up to 97%. The requirement for flocculants, as well as pH adjustment of the water, for effective FOG removal can be fully automated, using the Ecologix E-Series Dissolved Air Flotation System.

Process Description

- A DAF system utilizes a separation technique that injects microscopic air bubbles into the DAF tank.

- These tiny bubbles attach to the insoluble pollutant materials, floating them to the surface the way a life preserver keeps a person afloat.

- Certain materials used in the food processing are heavier than water. They require the addition of flocculants, which attract suspended contaminant particles and air. When combined, these two substances cause the pollutants to join in clusters and force them to float to the pretreatment vessel's surface.

- These accumulating contaminants at the surface of the DAF vessel are what is known as "sludge." They are then scraped off the surface of the water and removed from the treatment process.

- Clean water then exits at the bottom of the DAF vessel and can now be safely discharged to the sewer.

Ecologix Environmental Systems custom configures a full treatment system that can screen and treat the wastewater to discharge levels that meet or often exceed local municipal requirements. Please review our current offerings to the meat and poultry industry and call 1-678-514-2100 or contact us today to learn more about solutions we can offer your operation. You may be surprised how affordable a fully engineered, custom solution may be! We have specialized expertise in all food-related industries.